John Deere: SMO

The John Deere Sales and Marketing Optimization (SMO) interface transmits information about customers and equipment units for use in the John Deere SMO application for sales purposes.

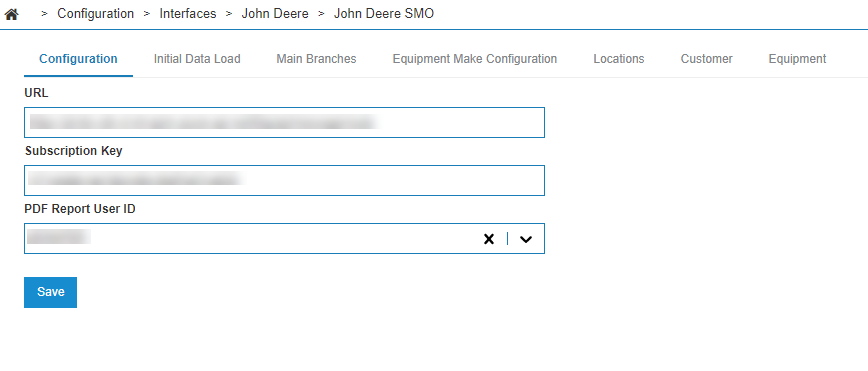

You can access the John Deere SMO from anywhere in IntelliDealer by navigating to Configuration > Interfaces > John Deere > John Deere SMO.

Topics in this section include:

Setting up the John Deere SMO Interface

Once the URL and subscription key are configured, the SMO interface begins the live transmit of customer and equipment add and update events.

Note: It is important to only add the URL and subscription key when you are ready to begin the initial data load process to allow the smooth flow of data from IntelliDealer to the SMO environment.

Prerequisites: You must have feature 6423 - John Deere SMO licensed.

-

From anywhere in IntelliDealer by navigating to Configuration > Interfaces > John Deere > John Deere SMO.

On this tab, setup the SMO URL and subscription key you received from John Deere. Or, if you are using OAuth, set the Client ID, Secret, Token URL, Scope, and Best Selling Price received from John Deere. Contact John Deere if you need assistance setting this up.

The Best Selling Price dropdown determines which price field is transmitted on equipment requests and.

Select a User Id to receive a PDF report for any errors encountered during the initial data load.

-

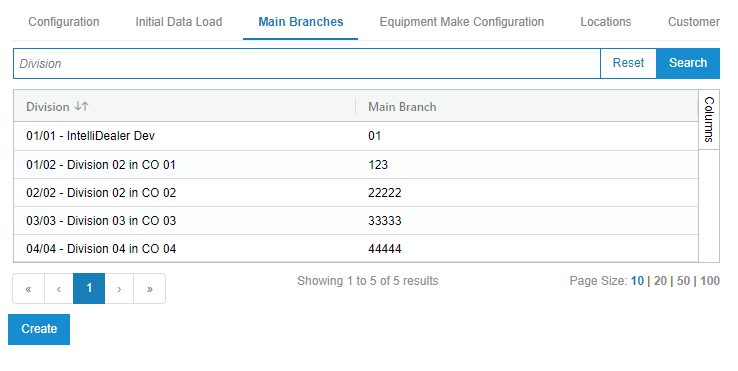

Click the Main Branches tab.

John Deere SMO requires that one location be designated as the main branch for each division.

-

For each IntelliDealer division, click Create. In the pop up, select the division and enter the one- or two-character branch code you wish to designate as the main branch for the division selected.

-

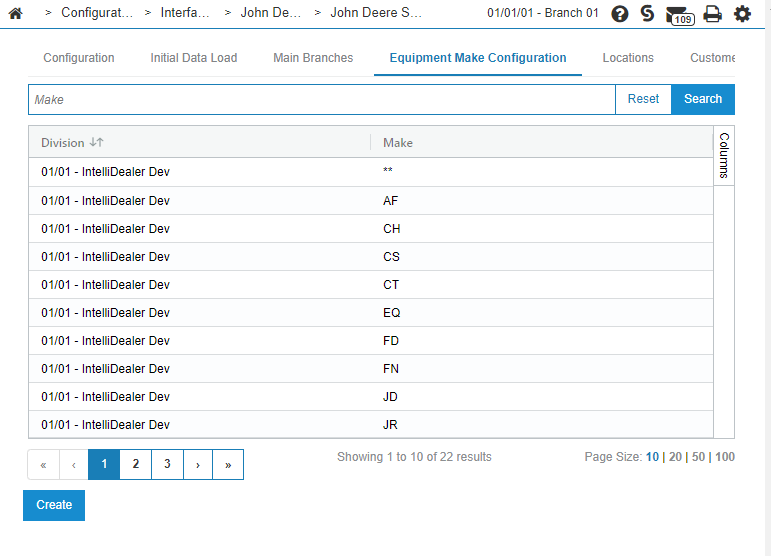

Click the Equipment Make Configuration tab.

On this tab you can configure a list of makes that determines which equipment units are transmitted to, and available in, the SMO system.

-

Click Create, then select a division. Then select a make code and click Save. Repeat this step for as many makes as you wish to add to the list.

-

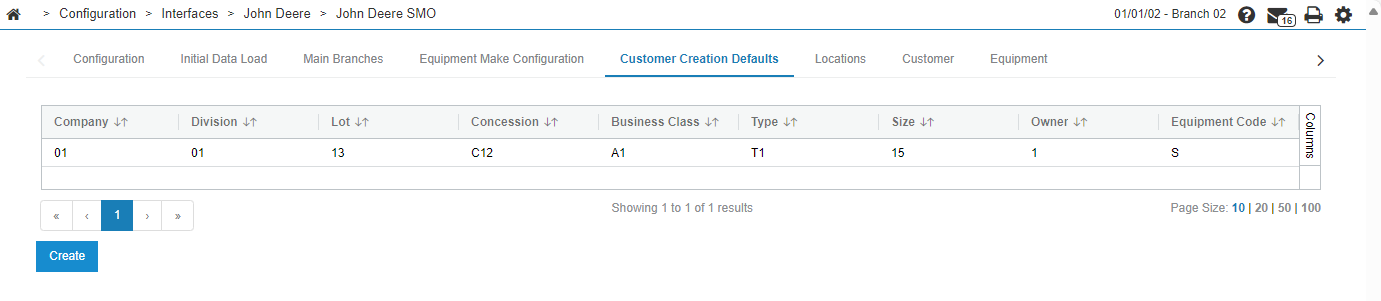

Click the Customer Creation Defaults tab.

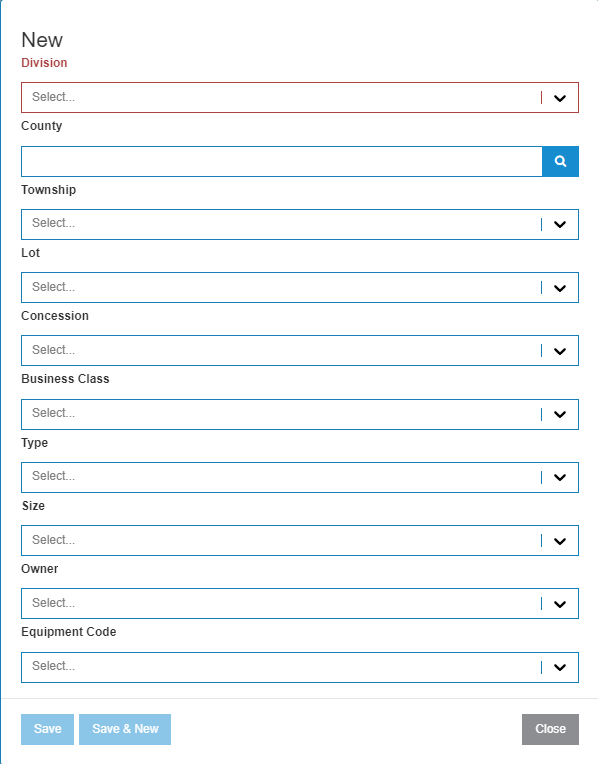

This tab lists default values to be used when creating a customer.

-

Click Create to create a new set of default customer values.

-

Fill in the fields with default values, then click Save and Close.

Initial Data Load

The Initial Data Load tab on the configuration screen allows you to transmit a baseline of multiple data sets from IntelliDealer to pre-populate the SMO system with customers, equipment, and other data created before the interface is turned on for the first time. This data load must be performed in order from top to bottom, as the SMO system has strict controls on entity relationships and the order in which they are added to the SMO system.

Radial Buttons: Submit Initial and Load Estimate

For each data load type on the Initial Data Load tab, you can select one of two radial button options:

-

Submit Initial—select this option to initiate the actual data load process. When you click the load button (for example, Submit Initial Location Load), the system begins transmitting the selected data type to the SMO system. This process may take some time, especially for large data sets like customers or equipment.

-

Load Estimate—select this option to view an estimate of how many records will be included in the data load without actually performing the load. This option calculates and displays the estimated number of records that would be transmitted, allowing you to plan for the data load process and understand the scope of the operation before committing to the full load.

The initial data load steps taken by IntelliDealer are:

-

Location Load—transmits locations from IntelliDealer. You must have completed the Main Branch configuration before this step can be run.

-

Customer Load—transmits all business and individual customers from IntelliDealer. This is one of the larger data loads and make take some time to run, potentially up to multiple hours.

Data is first loaded into a background data staging environment (called the "request queue") within IntelliDealer, after which the batch job shows as completed. Then the system begins transmitting the data to SMO.

-

Vendor Load—transmits only vendors associated with a customer record.

-

Make Load—transmits the make codes configured on the Equipment Make Configuration tab.

Tip: Ensure you have completed the Equipment Make Configuration step before beginning the data load or nothing will be transmitted.

-

Model Load—transmits all equipment models available in IntelliDealer that correspond with the configured make codes.

-

Franchise (Group Code) Load—transmits all group codes available in IntelliDealer. To prevent issues with the following loads, the group code system in IntelliDealer must be populated with every group code used by an equipment or stock record. If a unit is transmitted with a group code that is not present in the IntelliDealer group codes configuration, the unit will not be loaded into SMO.

-

Equipment Load—transmits all equipment units matching the configured makes configured. Similar to the customer load, this may be a very large data set and can take some time to run. It follows a similar transmit process to the customer load, wherein the data is loaded into the data staging environment and then transmitted to SMO.

This load only picks up units that are not flagged as attachments as SMO requires the unit an attachment is attached to be available in the system before transmitting the attachment itself.

-

Attachment Load—similar to the equipment load, this transmits attachments that match the make codes configured. This must be performed after the equipment load.

-

Equipment Notes Load—transmits all equipment notes (memos) for the units previously transmitted.

-

Equipment History Load—transmits all equipment history for the units previously transmitted. Note, this service is often referred to as the "cost transaction" service by John Deere.

Upon completing the initial data load, the SMO interface begins automatically transmitting create, update, and remove events for entities in the system. This process happens automatically as entities are modified and is not visible to the end user.

Manual Transmit

During normal operation, the John Deere SMO interface automatically picks up entities that are added, changed, or removed from IntelliDealer. However, as a back up option, you can manually transmit data to force an update on a particular entity using these tabs:

-

Locations—use this tab to Create, Update or Remove IntelliDealer locations in SMO. You should only be run this manually if a location has been added or removed from IntelliDealer.

-

Customer—use this tab to transmit customer and vendor records. Only vendors associated with a customer are transmitted.

-

Equipment —use this tab to manually transmit makes, group codes, and equipment units.