Dispersal

Use this page to set up dispersal of corporate inventory to the location with the highest demand. Parts Dispersal is similar to Parts Central Inventory, except that the central order is not created in the Central Location. Instead, it is split up and dispersed to the locations that are configured to use the Central Location. The orders are generated through the Create Stock Order process the same way that a central order is created.

Note: Since they both use the same method of determining centrally ordered parts, you cannot use this feature with Parts Central Inventory. If you are licensed for Parts Dispersal, your central inventory will always be dispersed.

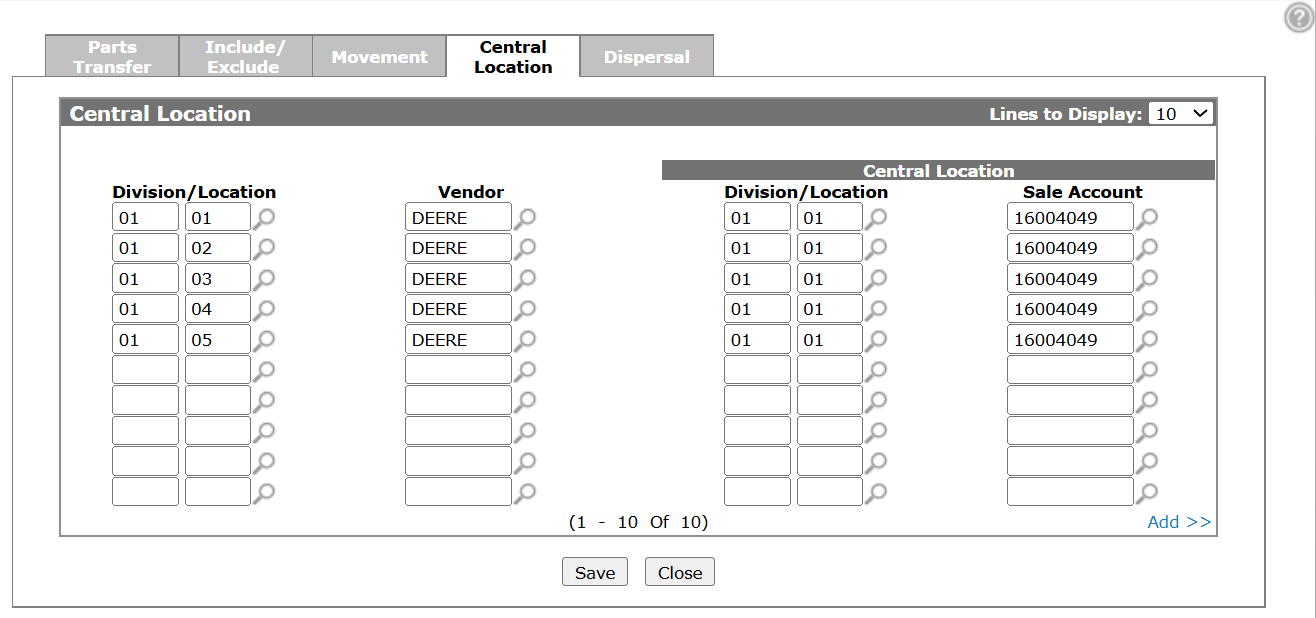

You can access the Central Location tab from the Parts Ordering screen by clicking Ordering Option > Stock Transfer/Central Inventory then clicking the Dispersal tab.

Topics in this section are:

Using the Dispersal Feature

You must first configure a Central Location, which not only determines which locations to look at when creating the orders, but also which locations the dispersed orders can be created in.

When a central stock order gets dispersed, only locations that are configured to use the Central Location can have orders created. The Central Location does not get any dispersed parts unless it is also configured as a valid location for Central Inventory.

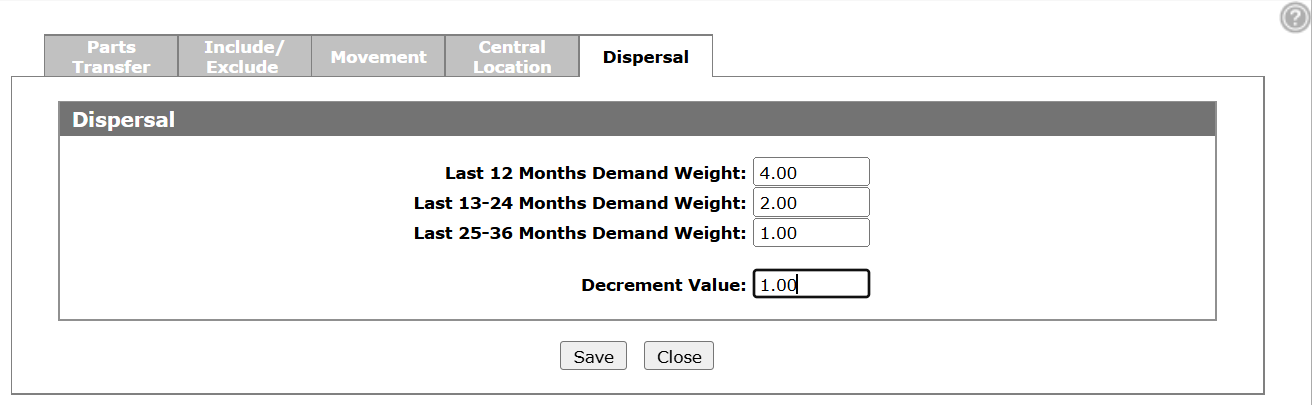

On the Dispersal tab, set the demand weighting per time frame and a decrement value. These values are used to generate a point total for each location based on the demands of the part. The location with the highest point total gets the dispersed part.

To create and disperse the Central Inventory to the locations configured to use the Central Location:

-

On the Parts Ordering screen click Ordering Options > Create Stock Order.

The Create Stock Order screen opens.

-

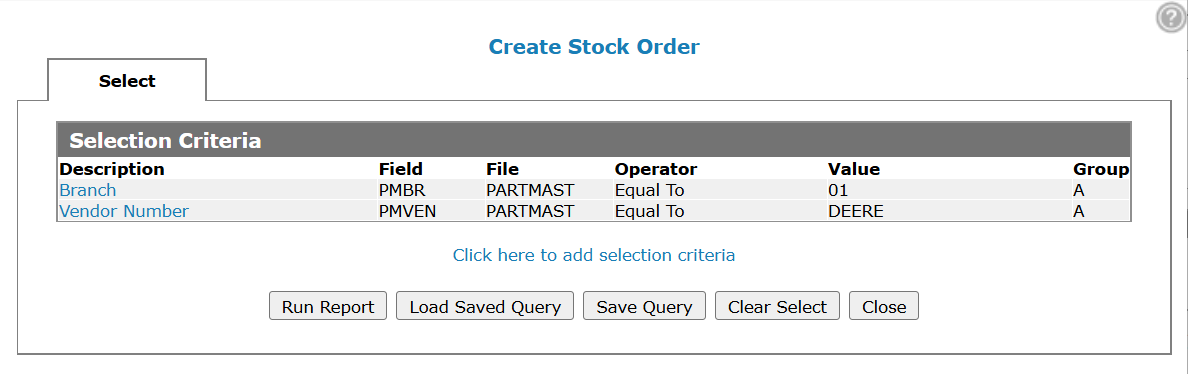

Click the Click here to add selection criteria link.

The Selection Criteria screen opens.

-

Add selection criteria for the central location and the vendor. You do not need to include the dispersal locations as part of the selection criteria.

-

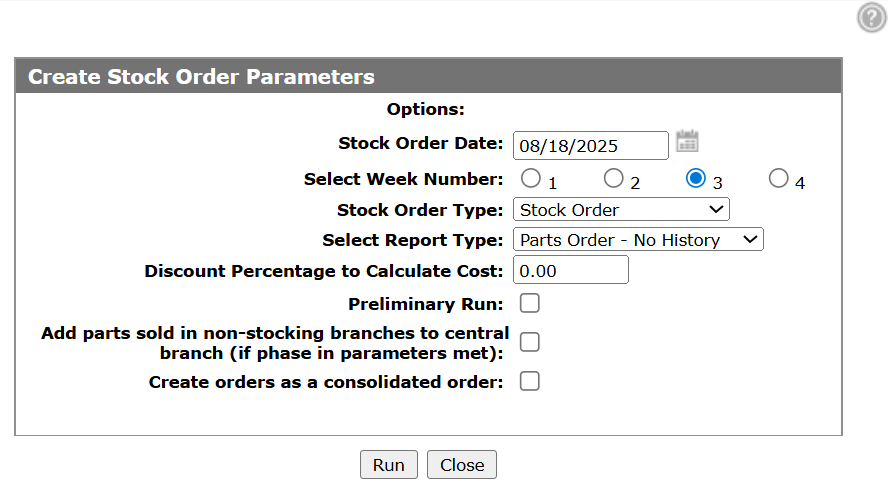

Click Run Report.

-

Click Run to submit the stock order.

When you submit the stock order creation IntelliDealer generates the dispersed stock orders. IntelliDealer analyzes each part ordered as Central Inventory, based on the demand weight, to see which location the part should be dispersed to. IntelliDealer only creates orders for locations that actually get parts dispersed to them, unless they are also creating their own stock order.

How is Dispersal Computed?

IntelliDealer only disperses parts to non-stocking locations because these are the only locations which are used to calculate the central order quantity. For a location to be checked for dispersal of a part, it must:

-

have the part in the part master

-

the part must be active

-

either the OFC code must be '5', or the Don't Order code must be a 'D'

The formula for dispersal is:

(L12 Demands * L12 Weight) + (L24 Demands * L24 Weight) + (L36 Demands * L36 Weight)

Where:

L12 = Last 12 months

L24 = Last 13-24 months

L36 = Last 25-36 months

For each part that is centrally ordered, IntelliDealer analyzes all locations that could receive the part using the formula above to get their starting point total. The location that has the highest current point total gets the part placed on its stock order. The quantity is equal to the package quantity of the part. The quantity ordered is then subtracted from the total quantity that needs to be ordered for the part, and the dispersal decrement value is subtracted from that location's point total. If there is still quantity that needs to be ordered, each location's current point total is again checked to see who has the highest. The highest location gets the part placed on its order. This process is repeated until all quantity has been ordered.

If there is a tie between two or more locations point totals, the store priority is used to see which one gets the part. If a location is not setup in the store priority, it is placed as the lowest priority. If there is a tie between locations that are not setup, the location that comes first alphabetically gets the part.

Protected Inventory

To stop the dispersed inventory from being automatically transferred by the system, IntelliDealer adds the protection code $PD$ to the inventory that was dispersed. The code is added to the Product Code field on the Parts Profile Ordering Information tab.

During stock order creation, the on-hand quantities are checked for each part being ordered. The on-hand quantity is a calculated value where

on-hand = on-hand + on order + back ordered - allocated - reserved

If a location has an on-hand quantity for a part, that quantity gets protected and removed from the stock order. If all of the required quantity was found on-hand, then the part is not ordered. If there is still some quantity required, then the part is ordered and dispersed.

Once the stock order has been received and updated by a location, any parts that were ordered as part of the dispersed inventory, but only in the quantity that was received, is protected. If there was already protected inventory at the location, the new received quantity is added to it.

Stock Order Dispersal Report

When the stock order creation completes successfully, a new Stock Order Dispersal Report (PSPO027 ) is generated showing the parts that were dispersed and what locations they went to. This report only prints if parts were actually dispersed. If no parts were ordered centrally, then the report does not print.

The heading of the report shows the Central Inventory location and vendor. In the extremely rare case that the vendor number on a part does not match between a location and the Central Location, the location and vendor will be from the order being placed. The report is sorted by the location, then the vendor number. There is a page break if the location or vendor number changes.

The detail lines on the report are:

-

part number and description—showing the total sales, demands, on-hand, and quantity ordered for all valid locations.

-

division and location—showing the part details for that location. The quantity ordered is the quantity that was dispersed to this location. This value is blank if the part was not ordered for this location.

Screen Description

Demand weight is a multiplication factor used to make more current purchases count for more than older purchases in the dispersal formula. See How is Dispersal Computed? for the formula.

The fields on the Dispersal tab are:

| Field | Description |

|---|---|

| Last 12 Months Demand Weight | The demand weight for the last 12 months. |

| Last 13-24 Months Demand Weight | The demand weight for the last 13-24 months. |

| Last 25-36 Months Demand Weight | The demand weight for the last 25-36 months. |

| Decrement Value | The rate at which to decrement the demand as the location's score is evaluated and parts are dispersed. |

Click Save to save your changes or Close to exit without saving.