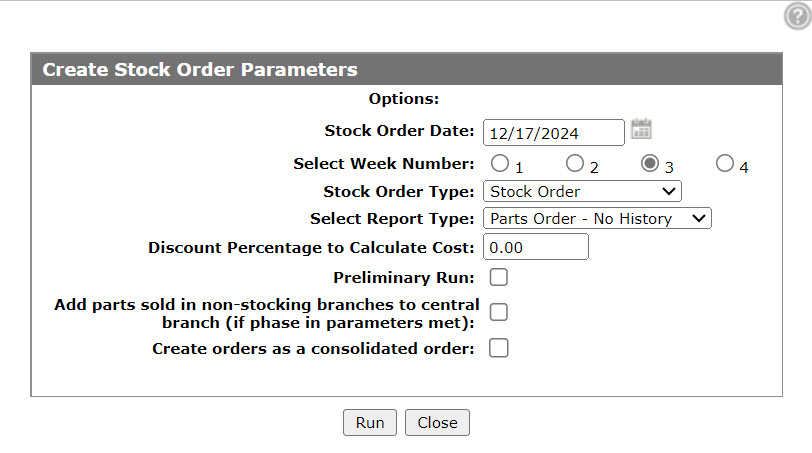

Create Stock Order Parameters

Use the Create Stock Order Parameters screen to select parameters for a stock order.

To open the Create Stock Order Parameters screen:

-

Navigate to Product Support > Parts > Parts Ordering.

-

Click the Ordering Options link and select Create Stock order from the drop-down.

-

Enter or load your selection criteria, then click Run Report.

Screen Description

The fields in the Options section of the Create Stock Order Parameters screen are:

| Field | Description |

|---|---|

| Stock Order Date |

This date is for printing purposes only. It is not used in determining the starting point for lead time. Instead, the software uses the current parts month with the week number entered to make its calculation. This date is not used to determine which month of the sales history to use as the current month when calculating order quantities. When an automatic order is created, the system date is used to determine the week number. When manually creating the order, the system defaults to the current date. Note: It is important to ensure that the parts month end procedure is run at the end of each month or the stock order program will be using the wrong month of sales history as the current month. |

| Select Week Number |

For order formula codes that use a lead time, the expected sales during the lead time must be

calculated. The lead time is specified in weeks, and sales history is maintained by the month. Week 1: 1st - 7th |

| Stock Order Type |

The stock order type. Valid values are:

|

| Select Report Type |

The stock order report type.

|

| Discount Percentage to Calculate Cost | A discount percent which accurately determines the cost of the parts that will be ordered. If no discount percent is entered, the part master current cost will be used for the cost of each part. If a percent is entered here, then the part master cost will be reduced by the discount percent entered. |

| Preliminary Run | Runs a preliminary stock order based on the parameters selected. |

| Add Parts Sold in Non Stocking Branches to Central Branch (if phase in parameters met) |

If selected, any parts in non-stocking locations that need to be ordered that do not exist in the central location, are added during the run and uses the sale account field defined on the Central Location tab. |

| Create Orders as a Consolidated Order | If selected, the system assigns a single consolidated order number to each parts order created by the stock order run. |

The fields in the Select Printer section on the Create Stock Order Parameters screen are:

| Select Printer | |

|---|---|

| Field | Description |

| Printer | The printer used for printing the stock order. |

| or PDF | Creates a PDF file of the stock order, which can be viewed via the PDF Viewer. |

The reports produced are:

| PAR156 | Parts Order Receiver |

| PAR221 | Group Update Receipts |

| PAR022 | Parts Order #'s Assigned |

| PAR007 | Parts Order |

| PAR187 | Non Stock Review Report |

| PAR188 | Weekly Transfer Report |

| CSO012 | Stock Transfer # |

| PAR190 | Re-Order Listing |

Use these buttons to complete your work on the Create Stock Order Parameters screen:

| Button | Function |

|---|---|

| Run | Generates the stock order run. |

| Close | Closes the Create Stock Order Parameters screen without generating the stock order run and returns to the Selection Criteria tab. |