Order Formula Code M

Note: A dealer must have at least one year of history generated on IntelliDealer before using this system.

The OFC code M (Min/Max) calculates and tracks parts ordering lead time, resulting in better alignment of ordering to the parts you sell, increased turns, and a better fill rate. This code can be applied to parts with no reclass and there is no need to add it to a reclass table.

Topics in this section are:

Average Order Cycle Days

The Parts Master (PARTMAST) file captures the Average Order Cycle Days (PMAOC) by part number. This field tracks the average number of days it takes from the release to the update of a part stock order (Emergency or MD-Type are not included in the calculation). This provides a true ‘lead time’ in days for each part. Most parts have a lead time of few days rather than weeks.

If an order is unreleased, the released date and time are reset to the date and time of the last release when the order is released again. This calculation can also be used with any existing OFC that uses a lead time.

The average order cycle is rounded up to the next whole day. For example, if the average order cycle days is 4.35 days then it is set to 5, if it is 3.85 it is set to 4 as the parts are received on the fourth day.

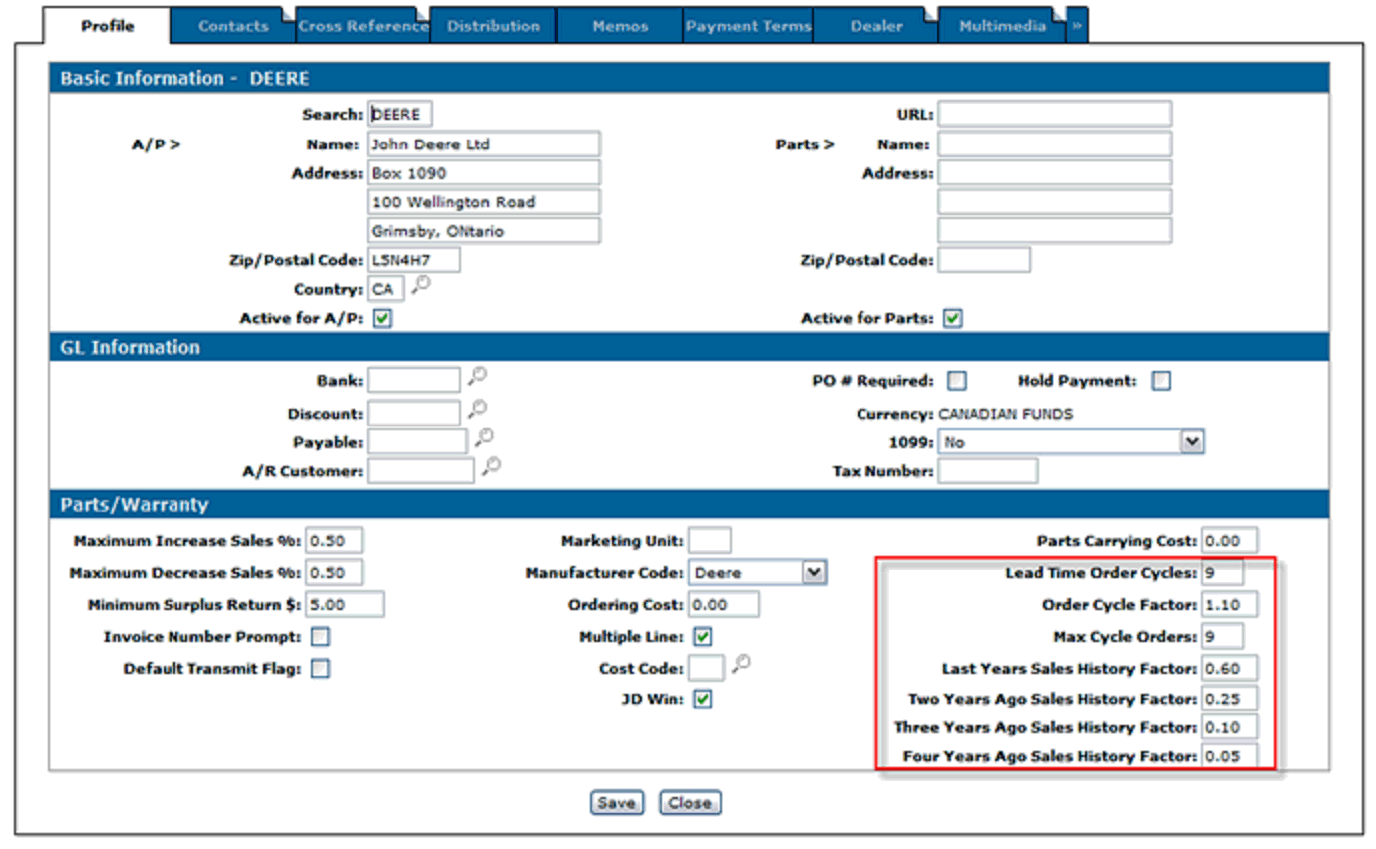

OFC M Fields on Vendor Profile

For parts that are assigned OFC M, the Lead Time is calculated based on the values entered in the Parts/ Warranty section of the Vendor Profile associated to the part and the Average Order Cycle Days of the part, which is the average number of days it takes from the release of an order to the update of an order. The Average Order Cycle Days of the part is calculated in the background and not displayed anywhere within IntelliDealer, however you can determine this value by running a query in the Data Miner utility using the PMAOC (Average Order Cycle Days) field. The Average Order Cycle Days value is always rounded up to the nearest whole number. For example, 4.35 days would be set to 5, 3.85 set to 4, etc.

The fields are:

Lead Time Order Cycles

The number of order cycles (parts order Release to Update) to look at when calculating lead time. This can be a value between 0 and 9. A value of 0 indicates that the lead time (in weeks) on the part profile is used. If the value is 1-9, and the number of order cycles (the number of times a part has been receipted) is greater than or equal the value in this field, then an actual lead time is calculated using the parts average order cycle days. This is effectively the minimum number of order cycles before the actual lead time is used,

Order Cycle Factor

Used to adjust the actual order cycle for the part up or down depending on the circumstances for the vendor. The factor for the vendor of this part is then applied to the average order cycle for the part to increase or decrease the actual average order cycle, if desired (a factor of 1.0 would leave the parts actual average order cycle unchanged).

Max Cycle Orders

The maximum limit of how many receipts to look at in calculating the average order cycle time.

Sales History Factors

There are four sales history factor values for the prior four years. These are used to place a weighting on the how important those years are in determining the average order cycle time. The four values must add up to 100%. The sales history factors are used to calculate a weighted sales history from the previous four years of sales – this is then used in the calculation of the sales during the lead time rather than just last year's sales as other OFCs use.

How Does the OFC Code M Calculate and Order Quantity?

The steps are:

1. Weighted Sales History

The first step in the process is that the system looks at the Sales History Factors and applies them to the sales values to determine the weighted sales history.

Here is an example of weighted annual history:

| Previous Months | Sales in that period | % Weight | Calculated Value |

|---|---|---|---|

| Last 12 | 100 | 60 | 60 |

| 13-24 | 80 | 25 | 20 |

| 25-36 | 120 | 10 | 12 |

| 37-48 | 102 | 5 | 5 |

| Total | 100 | 97 | |

Thus 97 is the weighted annual history.

2. Lead Time

Next, the system calculates the lead time for the part.

The system compares the number of order cycle orders (the number of times an order has been receipted for this part) to the vendor master minimumLead Time Order Cycles orders. If the number of order cycle orders is greater or equal to the minimum lead time order cycle orders and is not zero then an actual lead time is calculated (in days) using the parts average order cycle time from its previous ordering history.

If PMOCO >= VMLOC then use PMAOC

Note: The PMOCO field is not displayed anywhere within IntelliDealer but the value for it is tracked in the background. As with PMAOC, the PMOCO for a specific part can be determined by running a query using the Data Miner utility and selecting the PMOCO field.

Depending on the circumstances for the vendor, the system may use an Order Cycle Factor to adjust the actual order cycle for the part up or down. This factor for the vendor of this part is then applied to the average order cycle for the part to increase or decrease the actual average order cycle if desired (a factor of 1.0 would leave the parts actual average order cycle unchanged).

PMAOC * VMOCF = AOCLDT in day.

The actual lead time calculated in days is then divided by 7 to get the lead time in weeks.

AOCLDT/7=AOCLDT in weeks. This will be LDT

3. Reorder Point

The system calculates the reorder point (ROP) using the current week number and the weighted sales by month. The week number refers to the week of the month in which the stock order is being run - first week of month through fourth week of month.

-

If LDT = 4.5 weeks and the week number is 1 then the ROP is calculated as:

75% of this month last year (3 weeks) plus 25% of next month last year (1 week) plus 0.5*25% of next month last year (0.5 weeks) giving a total of 4.5 weeks sales history

-

If LDT = 8.3 weeks and the week number is 2 then the ROP is calculated as:

50% of this month last year (2 weeks) plus 100% of next month last year (4 weeks) plus 50% of 2 months from now last year (2 weeks) plus 0.3*25% of 2 months from now last year (0.3 weeks) giving a total of 8.3 weeks sales history.

Note: It is recommended that you do not use OFC M on new parts (less than a year's sales) as the ROP would be 0 in this case.

4. Min/Max

The ROP(Reorder Point) is now the minimum.

If the ROP is a decimal it is rounded up to the next whole number. This is done in order to ensure parts are ordered when the lead time is small or the sales history is small. For example, a part that has one sale in a month and its average order cycle is four days - the ROP would be calculated as 4/7*0.25*1 or .14 which would round to zero. Rounding up ensures we order the one required. (4/7 coverts 4 days into 0.57 weeks)

All other OFC codes use this month last year unadjusted when calculating the sales during this period last year. OFC code M has enhanced this calculation by subtracting the current month sales from this month’s sales last year and using that quantity in the formula above to calculate the ROP. For example, consider that the sales this month last year were 50 and current month sales are already 44, other OFC codes would still use 50 in the ROP calculation. OFC code M will use 50-44 or 6. This quantity is also adjusted depending on the number of weeks remaining in the month. Consider that there is only 1 week left in the month (current week is 3) then 0.25 times 6 would = 1.50, which is insufficient. To compensate, the system adjusts the remaining current month quantity to obtain the proper order quantity (6 is reset to 24), so 24*0.25=6 thus the proper quantity 6 is ordered. Similar adjustments are made if the week is 1 or 2. Consider if the week was 2, then the quantity of 6 would be adjusted to 12 so 12*0.25+12*0.25=6.

The maximum is then calculated by applying the safety stock (SS) to the minimum. If the SS was a fixed quantity of 10 and the minimum was 43, then the maximum would be minimum + SS or 53. If the SS was 10% and the last 12 months weighted sales were 123 then the safety stock would be 123*0.10 or 12 thus the maximum would be 43+12 or 55.

5. Order Quantity

The system now checks to see if an order is required.

If the net on hand plus on order plus on back order is less than the minimum then an order is triggered. The order quantity would be maximum - net on hand - on order - on back order.

If this is the first order in a month (i.e. week number is 4) then the order quantity is adjusted to ensure there is enough ordered on this stock order to fill the entire month's demand. For example, if the sales last year for the month are 10, and the order quantity using the above formula is 6, then the order quantity will be adjusted to 10 (assuming there is none on hand or on order). This is done to prevent the part from being ordered in smaller quantities per order on each of the stock orders for the month. That is, it will prevent ordering 6 on the first stock order, 1 on the next,, 2 on the next, etc. for each stock order during the month. This brings the inventory in at the start of the month all on one order. The part will reorder on subsequent stock orders if more parts are sold this year than were sold last year during this month.

This quantity would then be adjusted by pieces per set, parts per package and package quantity as is the case with every order.

You run it with the normal week # that you would use for the stock order run - if it is week 1 use week 1.

The reason week 4 orders and 3 may not order is that it is looking at next month’s sales in week 4 – week 3 is still looking at current month - if the system calculated lead time on the part is long enough it might look at next month but that is not likely as the system lead time is usually just a few days

When week 4 is run it always tries to order enough for the entire month on the first stock order run for the month – this is because the system does not know when in the month the sales occurred in (could all have been sold in the first day of the month or the last day of the month) – this is also done to reduce stocking time – instead of ordering 1 qty, 4 times in the month it will order a qty of 4 once so you only process the part once

The suggested order option uses the same programs as stock orders so they will be consistent in the ordering logic.

Revision: 2025.02