InspectionPlus Template Builder

Return to the InspectionPlus Homepage.

The Template Builder screen is where users can create and edit templates for a number of different types of inspections. Templates are Published and become Inspection Forms that are then used for whatever job purpose is required of them.

| Icon | Description |

|---|---|

|

|

Physically moves steps up or down the sections. |

|

|

Collapses or expands the section. |

|

|

Opens a list of options including:

|

Topics in this section include:

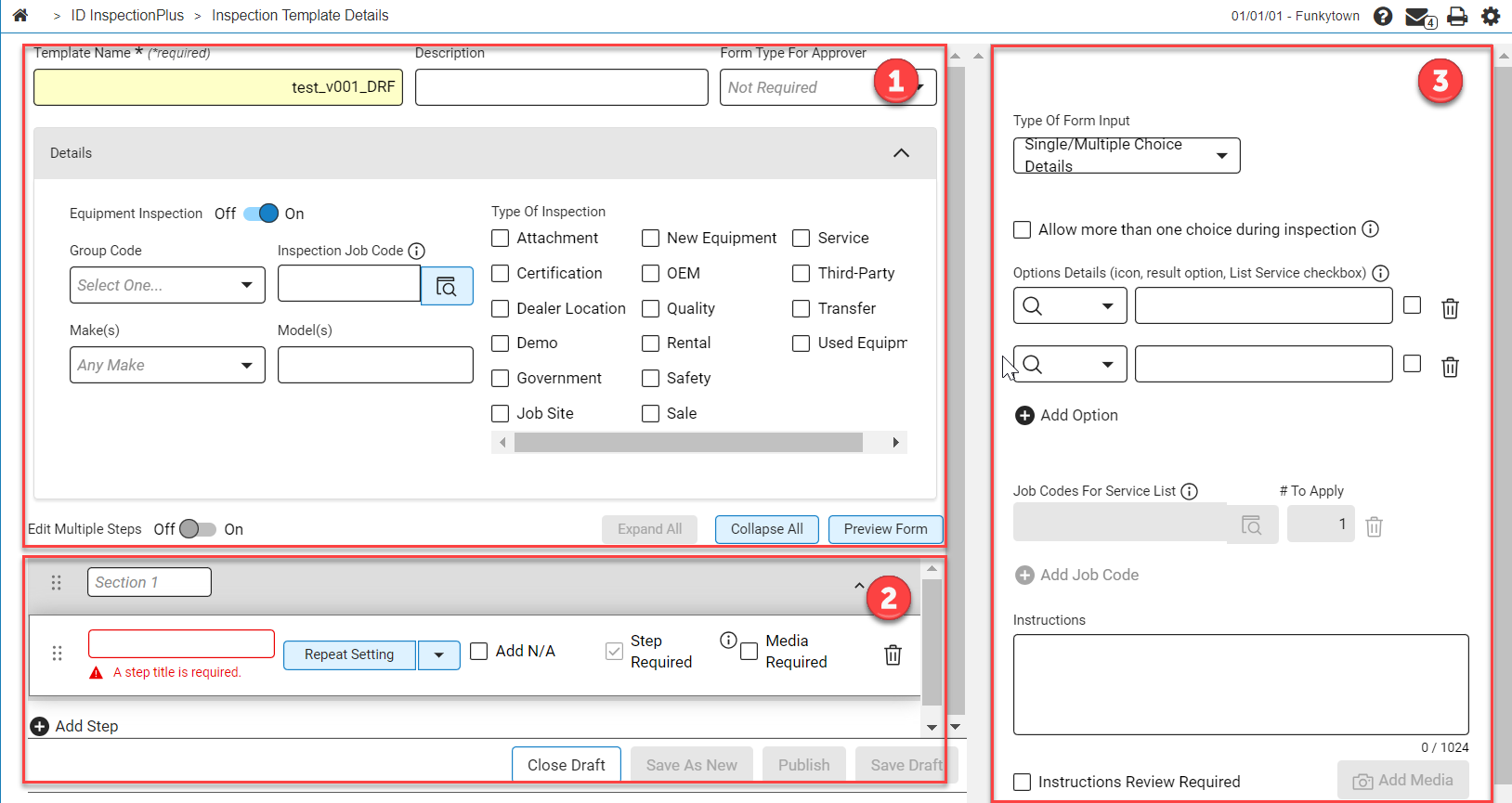

Template Details

This section controls the filtering options used to classify the type of template or form you are creating or using.

For more information Template Naming and Deleting a Template.

The Type Requiring Approval dropdown controls who approves the form.

You can filter by Group Code, Inspection Job Code, by the Make and Model of an equipment unit, or by the type of inspection.

The Type of Inspection options control what appears in the Type field where Forms are listed.

Inspection Steps

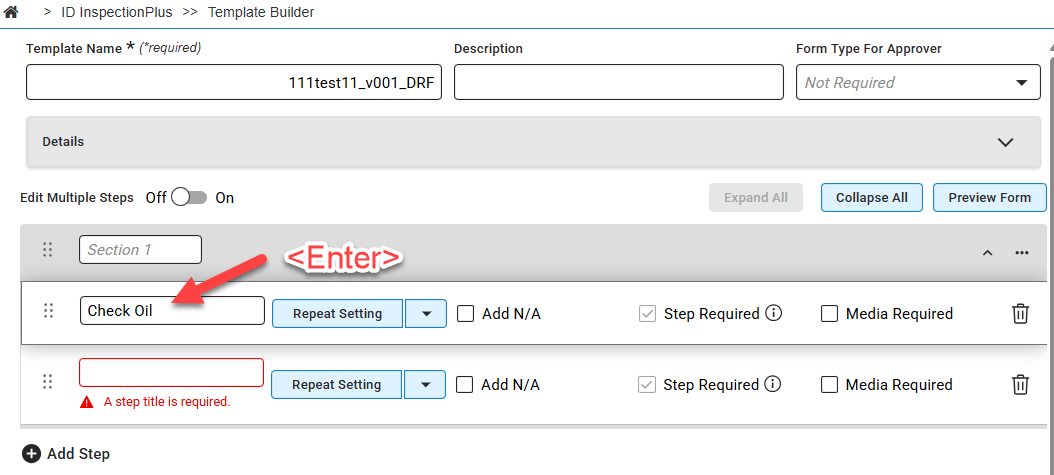

This section is where the actual creation of an inspection form is done.

After entering a Step Title, the enter (or return) key automatically adds a new step.

Options configured in the previous step are also saved and copied to any newly added steps.

These checkbox options are available for each step added to the form:

-

Add "Not Applicable": Checking this box on a step is useful in cases where certain steps my not be relevant to every situation or item. It also provides a way to indicate when a step was intentionally skipped.

-

Step Required: Checking this box ensures that this step is required in order to complete the form.

-

Photo/Video Required: Checking this box ensures that attaching a form of multimedia to the step becomes a condition for the completion of that form.

Steps can also be individually removed by clicking the Trash icon.

If erroneous text is entered into one of the step fields, the Add Step button is locked until the error is corrected. This prevents a template from being created that might produce errors.

Condition Per Step

This section displays an expanded list of conditions that can be applied to the step. The condition determines what the step is meant to evaluate.

The Type of Form Input dropdown changes the manner the inspection step is completed.

This is a list of the types of form inputs:

| Type of Form Input | Description |

|---|---|

| Single/Multiple Choice |

In the form the step becomes a list of options that can describe a list of categories like Pass or Fail. (ex. Good Condition, Some Wear, Needs Repair.) Example of an Single/Multiple Choice based step: a general evaluation of parts or equipment with a choice of representative conditions. |

| Text Field |

In the form the step becomes a text field that can either contain only numbers or numbers and text. Example of a Text Field based step: a technician can enter specific responses on a step for a tire replacement. |

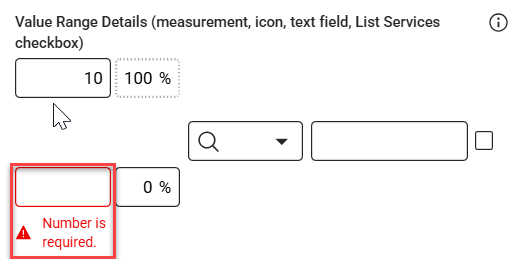

| Value Range |

In the form the step becomes a field where a value can be entered. This is used to indicate a quantity out of a hundred that might be required or a number out of a maximum required amount of a specific item or a piece of equipment. Example of a Value Range based step: a step that would determine the diameter of apples in a yield. A value range would be:

A Conversion Option is available for converting one unit of measure into another.

|

| Spec Range |

In the form the step becomes a specification range where a value for specification is defined. Details for what In Spec and Out Spec means for that inspection form can also be defined. Example of a Spec Range based step: a step that would measure the oil viscosity used. A common specification for engine oil viscosity is SAE 5W-30. The "5W" stands for winter, which indicates the oil viscosity at cold temperatures. The "30" indicates the oil viscosity at high temperatures. A spec range would be:

|

| External/Customer Note |

If this option is selected then the step becomes a reference to external material provided elsewhere but related to the inspection. Example of an External/Customer Note on a step: a step that might require supplemental information, clarification of definitions, or historical context. |