Designating Surplus Inventory in a Multi-Store Environment

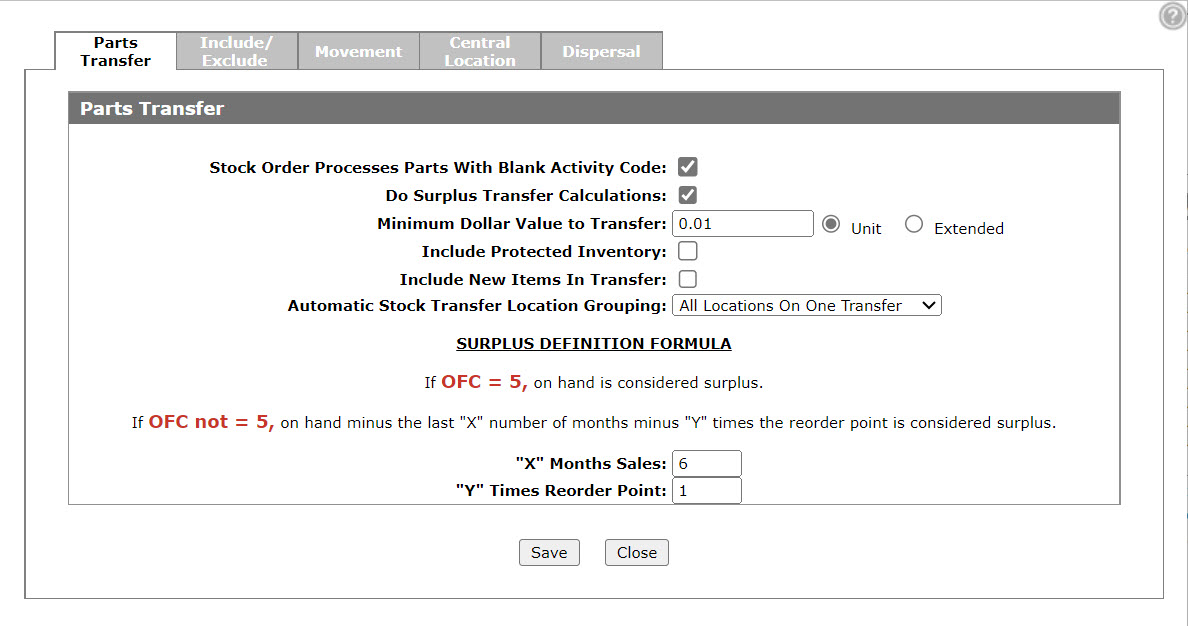

The Surplus Inventory Transfer system transfers parts from any location with a surplus to a location with a parts requirement. The Part Transfer tab is used to set the parameters for stock transfers between locations and identify central inventory locations.

To set up stock transfers:

-

From anywhere in IntelliDealer, navigate to the Product Support > Parts > Parts Ordering.

The Parts Ordering screen appears.

-

Hover over the Ordering Options link and select Stock Transfer/Central Inventory from the pop-up menu.

-

On the Parts Transfer tab, configure transfers referring to the Parts Transfer Screen Description.

The entire on hand is considered surplus for all OFC 5 parts. All parts with other OFC codes use the X month sales and Y times reorder point. This factor exists for any parts that do not have enough sales history. Only branches on the Parts Store Priorities screen are considered for surplus when calculating the stock order.

If running a stock order for a location classified as the central location, the system adds all sales for non-stocking locations together to determine the proper stocking criteria for the central location. It will look at all non-stock parts in all locations even if the part is not currently loaded in the location branch.

-

Click Save to save changes made on the Parts Transfer tab.

-

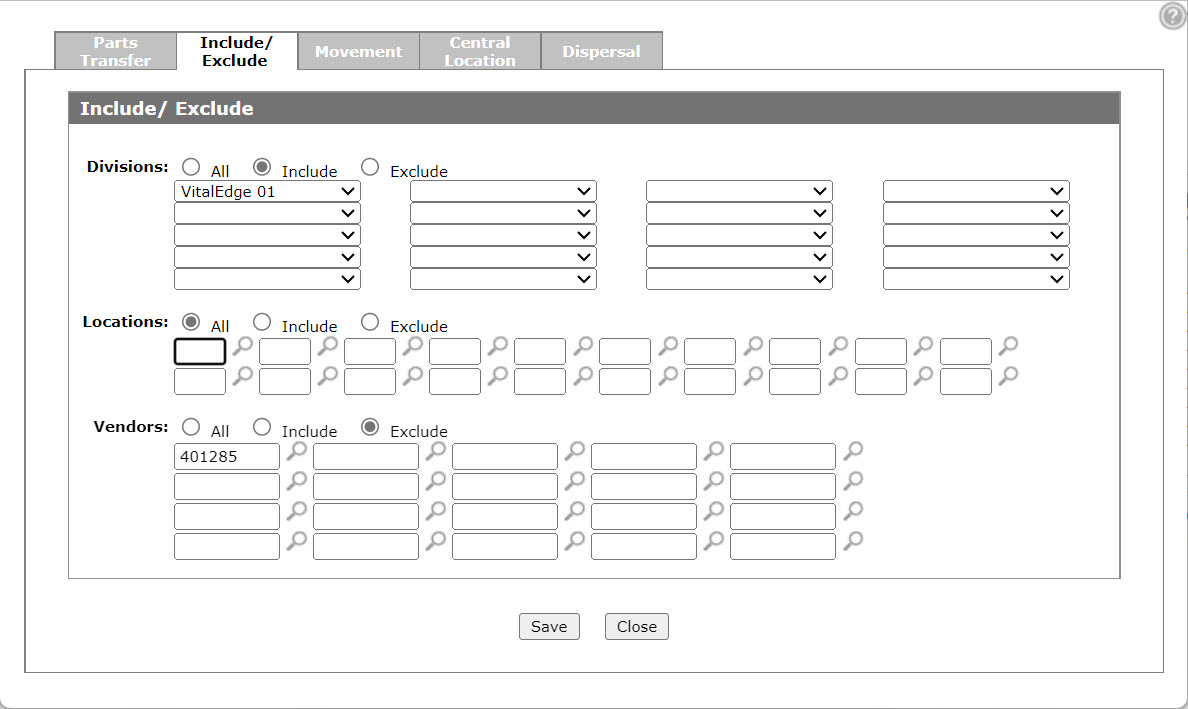

Click the Include/Exclude tab.

-

Indicate which Divisions, Locations and part Vendors are to be included or excluded from the transfer.

-

Click Save to save changes made to the Include/Exclude tab.

-

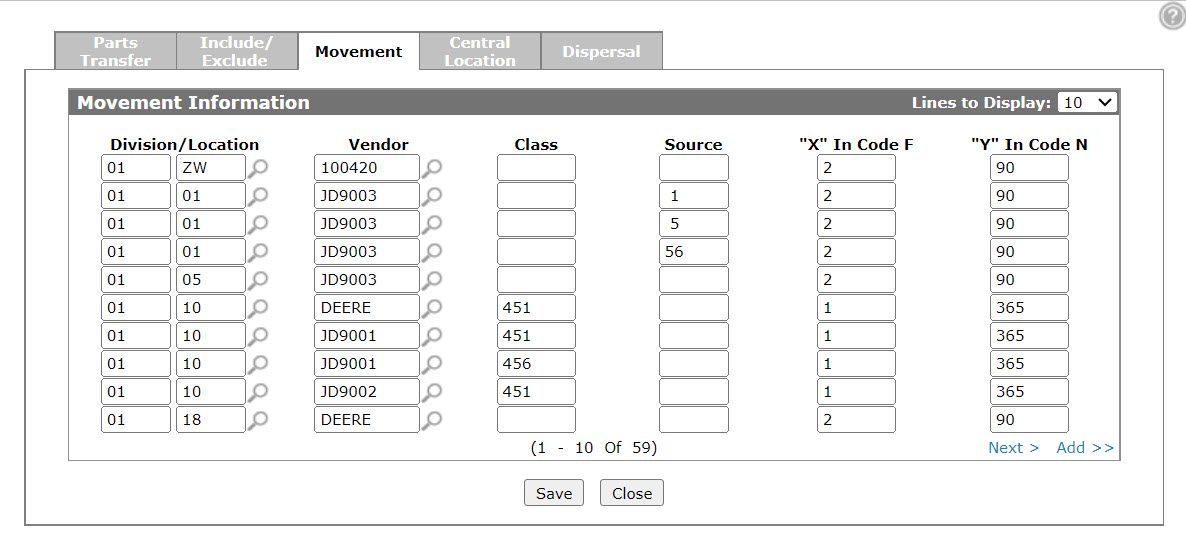

Click the Movement tab.

-

Click the Add>> link to add new movement information and fill in the fields referring to the Movement Information tab.

-

Click the Save button to save changes made to the movement codes.