Order Formula Code Calculations

The calculations involved for Order Formula Codes (OFC) are:

-

OFC 1 Calculation—for parts with a seasonal increasing or decreasing demand of 10 or more sales

-

OFC 2 Calculation—for new parts with no or little sales history

-

OFC 6 Calculation—for manually controlling reordering parts.

-

OFC 7 Calculation—for slow moving parts, maintains one part on hand

-

OFC 8 Calculation—for slow moving parts, maintains two or three parts on hand

-

OFC 9 Calculation—regular stock order for parts

-

OFC D Calculation—for slow moving parts, maintains two parts on hand

-

OFC M Calculation—for all parts; it automatically calculates and tracks parts ordering ‘lead time’, resulting in better alignment of ordering to the parts you sell, increased turns and a better fill rate

See also OFC Reclass and Parts: Ordering Information.

OFC 1 Calculation

For OFC 1 parts, IntelliDealer uses the Reorder Point variable to reflect the seasonality of the part. The Reorder Point is higher during the demand season and lower or zero during the months of no demand.

The system calculates the Reorder Point based on the Lead Time, Safety Stock, and sales for the last year (L12 as shown in the Sales Summary of the Parts Profile). Last year's sales (L12) are automatically adjusted if a sales increase has occurred in the last 12 months compared to last year. The system applies this factor when calculating the Reorder Point to produce a more accurate Reorder Point.

The sales increase factor is limited to 1.0. If a sales decrease has occurred, no sales increase is applied. There are often factors which affect expected parts sales that should also be considered. For example, crop failure (for AG dealers), housing starts (for industrial dealers), etc. If sales this year are expected to be higher or lower than sales last year, the Effectual % and Number of Months fields on the Parts Profile can be used to further adjust last year's sales when calculating the Reorder Point. TheEffectual % is applied to the sales history before any Reorder Point calculations are made.

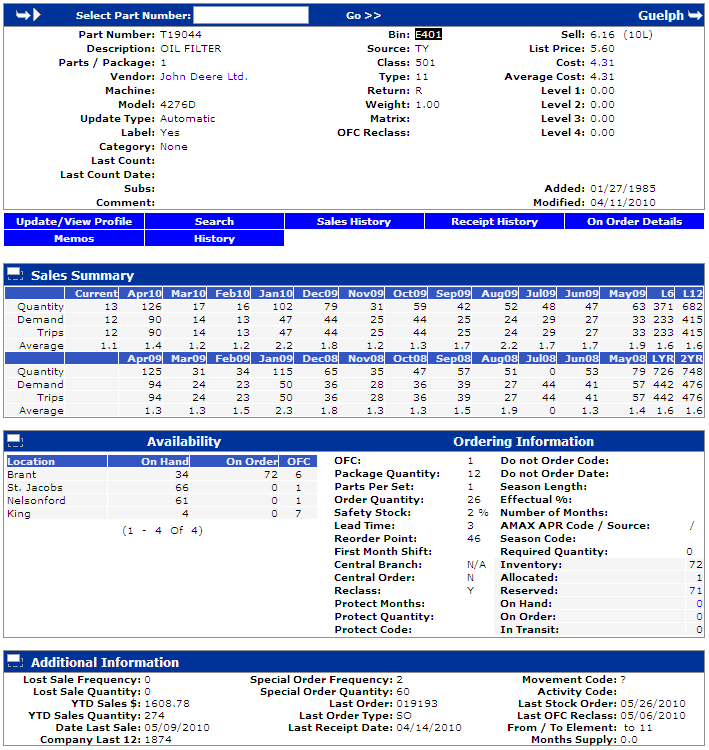

Consider the following OFC 1 part:

The steps the system uses in the calculation are:

-

Apply Effectual %. This part has no Effectual %, so the sales history is not adjusted.

-

Calculate expected sales during the Lead Time specified on the part to generate a Reorder Point.

Lead Time is specified in weeks, sales history is maintained by the month. When calculating the expected sales during the Lead Time, one month is assumed to equal 4 weeks. When creating the stock order run, the terminal operator must enter what week of the month it is. For example, the 1st week, 2nd week, 3rd week or 4th week of the month. If the week number is 1 then there are 3 weeks remaining in the current month, etc.

For example, assume that the week number entered is 3. Because the Lead Time specified on this part is 3, the Reorder Point would be calculated as :

1 week or 25% of sales this month last year (May 09, after being adjusted by Effectual %) plus 2 weeks or 50% of next month last year (June 09, after being adjusted by Effectual %) =

= 25% of sales this month last year (0.25 x 63) + 50% of sales next month last year (0.50 x 47)

= 39.25Tip: If the result of this calculation is a negative number, use zero. Remember that parts returns can cause negative sales history.

-

The Safety Stock is applied to the last 12 months actual sales (L12). This calculation only applies if the Safety Stockvalue is a %. If it is a fixed value (F), then no calculation is required.

In this case, the Safety Stock is 2%. As such, the calculation is:

(L12 X Safety Stock) = 682 X 0.02 = 13.64 (Safety Stock)

Tip: If the result of this calculation is a negative number, use zero.

-

Add the Safety Stock to the Reorder Point calculated in step 2 to adjust the Reorder Point. In this case, the calculation is:

Safety Stock from step 3 + Reorder Point from step 2 =

13.64 + 39.25 = 52.89 (Adjusted Reorder Point) -

The increase/decrease sales factor is then calculated as the last 12 month's sales (L12, before being adjusted by effectual %) minus last years sales(LYR), divided by last years sales(LYR). The calculation is:

(L12 - LYR)/LYR =

(682 - 726) / 726 = -0.093 (Sales Factor)This factor is limited to 0.50 maximum and -0.50 minimum. For example:

-

If last years sales (LYR) were zero and the last 12 months sales(L12) were greater than zero, the sales increase factor would be set to 0.50.

-

If last years sales(LYR) were greater than zero, and the last 12 months sales (L12) were less than zero, then the sales increase factor is set to -0.50.

-

If both last years sales (LYR) and the last 12 months sales (L12) were less than zero or equal to zero, a factor of 0 is used.

-

-

The Reorder Point from step 4 is now adjusted by the Sales Factor from step E. The calculation is:

Reorder Point + (Reorder Point x Sales Factor) =

52.89 + (52.89 x -0.093) = 47.97 (Reorder Point, rounded up to 48) -

The Reorder Point is limited by the last 12 months actual sales (L12) (sales history before being adjusted by effectual %).

-

If the Reorder Point, (48 in this example), is greater than the last 12 months sales (L12), then the last 12 months sales is used.

-

If the Reorder Point is a negative value, it is reset to zero.

-

If the Reorder Point is less than the Safety Stock, it is reset to match the Safety Stockvalue.

Note: This final calculated Reorder Point value ios loaded into the Reorder Point field in the Parts Profile.

-

-

The actual On Hand(on hand less allocated) + On Order + Back Ordered quantity is now compared to the Reorder Point.

If it is less than the Reorder Point, then an order is required for this part.

On Hand + On Order + Back Ordered

0 + 0 + 0 = 0

0 is less than 48 so an order is required.

-

The Order Quantity is calculated as the amount below the calculated Reorder Point for an OFC 1 part.

48 - 0 = 48

OFC 2 Calculation

You can use order formula code 2 for parts with no or very little sales history. The system determines the Reorder Point using the sales for the Current month plus the sales in the most recent months as specified on the Parts Profile.

The steps the system uses in the calculation are:

-

Effectual % is not allowed for OFC 2, so the sales history is not adjusted.

-

Apply the Lead Time to the largest of either the Current month's actual sales, previous month's sales, or sales from two months ago. For example, if the current month's sales is 2, the previous month's sales was 0, and the sales from two months ago was 1, then the largest sales Demand is 2.

The sales demand per month is divided by 4 to obtain a weekly sales demand. Therefore, assuming the Lead Time was 5, the reorder point is calculated as:

(Largest sales demand month x Lead Time) /4 = ( 2 x 5) /4 =

2.5 (Reorder Point)If the reorder point calculated is less than zero, then the system uses zero.

-

The Safety Stock is applied to the last 12 months of actual sales (L12), if the Safety Stock is a percent. If it is a fixed value then no calculation is required. For example, if the Safety Stock on the part was 20%, the calculation would be:

Safety Stock = L12 x 0.20 = 1 x 0.20

= 0.20 (Safety Stock)If the safety stock is calculated as less than zero, then the system uses zero.

-

The Safety Stock is added to the Reorder Point from step 2, to derive a new Reorder Point. For example, if the original Reorder Point on the part was 2.5, the calculation would be:

Original Reorder Point + Safety Stock = 2.5 + 0.20 =

2.7 (New Reorder Point)The new Reorder Point is then compared to the original Reorder Point. If the new Reorder Point is larger, then the new Reorder Point replaces the original Reorder Point. If the new Reorder Point is lower, then the original Reorder Point is used. In this case the new Reorder Point (2.7) is greater than the original Reorder Point (2.5), so the Reorder Point becomes 2.7, which is rounded to 3.

Note: If a new Reorder Point is calculated here, it is loaded in the Reorder Point field on the Parts Profile. Since the calculated Reorder Point is compared to the original Reorder Point to determine which is larger, it is compulsory to enter a Reorder Point when adding an OFC 2 part to the system, or changing a part's OFC to 2.

-

The Reorder Point is used to determine whether the part should be ordered and, if so, what the Order Quantity should be. This is done by comparing the Reorder Point to the On Hand + On Order + On Back Order quantity; if the On Hand + On Order + On Back Order quantity is less than the Reorder Point, the part should be ordered.

For example, assuming the Reorder Point was 3 and the On Hand, On Order and On Back Order quantities were 0, the Order Quantity would be calculated as:

Reorder Point - On Hand quantity - On Order quantity - On Back Order quantity = 3 - 0 - 0 - 0 =

3 (Order Quantity) -

The Order Quantity amount must be compared to the Economic Order Quantity (EOQ) for the part, which is calculated as:

Square root of {Last 12 months actual sales (L12) x (largest of last month, 2 months ago, or 3 months ago sales) x Ordering Cost / 0.12 x Net Price} =

Assuming the L12 of the part was 3, the last 3 months of sales were 0, 1 and 0 respectively, the Ordering Cost was 0.5 and the Net Price was 9.40, the calculation would be:

√(3 x (largest of 0,1, or 0) x 0.5 / (0.12 x 9.40) =

√(3 X 0.5) / (0.12 X 9.40) =

√1.5 / 1.128 =

√1.33 =

1.15, rounded to 1The Economic Order Quantity is limited to the last 12 months sales. The EOQ calculated here is loaded into the Order Quantity field of the Part Profile. The ordering cost used was 50 cents. If this was a non-Deere part, the ordering cost would have been $1.00.

-

The Order Quantity calculated in step 5 is compared to the EOQ calculated in step 6. Because the Order Quantity (3) is larger than the EOQ (1), 3 parts would be ordered. If the Order Quantity was lower than the EOQ, then the EOQ would be used as the order quantity.

OFC 6 Calculation

For parts that have been assigned OFC 6, the Reorder Point and Order Quantity must be set manually and are not automatically re-computed or modified by a stock order run. The Reorder Point and Order Quantity remain unchanged until you edit the parts profile, or an auto reclass is run (which occurs as part of a stock order), based on the specifications outlined on the OFC Reclass screen (if applicable).

The Order Quantity functions similarly to an Economic Order Quantity (EOQ) in that it is the minimum amount that will be ordered. The Order Quantity will also usually increase as the price of the part decreases.

The steps the system uses in the calculation are:

-

The Reorder Point of the part is used to determine whether the part should be ordered and, if so, what the Order Quantity should be. This is done by comparing the Reorder Point to the On Hand + On Order + On Back Order quantity; if the On Hand + On Order + On Back Order quantity is less than the Reorder Point, the part should be ordered.

For example, for a part with a Reorder Point of 3, an On Hand quantity of 1, On Order quantity of 1, and an On Back Order quantity of 0, the Order Quantity is calculated as:

Reorder Point - (On Hand quantity - On Order quantity - On Back Order quantity) = 3 - (1 + 1 + 0) = 1 (Order Quantity)

-

The Order Quantity calculated in step 1 must be compared to the Order Quantity on the Parts Profile . Whichever is larger is the order quantity. Therefore, assuming the Order Quantity on the Parts Profile was 2, then 2 parts would be ordered.

Using OFC 6 to maintain a fixed On Hand Quantity greater than 2

The Order Quantity can be zero. This is another way of maintaining a fixed On Hand quantity. Other order formula codes allow for a fixed quantity of 1 (OFC 7) and 2 (OFCs 8 and D). OFC 6 can be used to maintain a fixed quantity greater than 2.

For example, if 4 parts need to be maintained in inventory, on a part that has been assigned OFC 6 set the Reorder Point to 4 and the Order Quantity to 0. This will cause the system to maintain 4 parts in inventory.

Using this example, if the On Hand quantity was 4 and 1 part was sold, the Order Quantity would be calculated as follows:

Reorder Point - (On Hand - On Order - On Back Order) =

4 - (3 - 0 - 0) = 1 (Order Quantity)

When this order is placed, it will bring the inventory back to 4.

OFC 7 Calculation

This code is used for slow moving parts, (5 sales or less per year with no more than 1 sales Demand in any month).

When assigned to a part, OFC 7 attempts to maintain an On Hand quantity of 1 at all times. If the On Hand + On Order + On Back Order quantity for a part with OFC 7 assigned to it is less than 1, then an order is required. If an order is required, then 1 part is ordered.

OFC 8 Calculation

This code is used for slow moving parts, (10 sales or less sales per year with no more than 2 sales Demands in any month).

When assigned to a part, OFC 8 attempts to maintain an On Hand quantity of 2 or 3 at all times. If the On Hand + On Order + On Back Order quantity for a part with OFC 8 assigned to it is less than 2, then an order is required. If an order is required, then 2 parts are ordered.

It is possible to have an On Hand quantity of 2 or 3 parts with OFC 8. For example, if a part has an On Hand quantity of 2 and 2 are sold, then 2 will be ordered, making the On Hand quantity 2 again. If that same part has an On Hand quantity of 2 and 1 is sold however, 2 will be ordered resulting in an On Hand quantity of 3.

OFC 9 Calculation

The formula used for OFC 9 depends on the Lead Time of the part that the code is assigned to:

-

Quarterly OFC 9—for parts ordered only once each quarter, the Lead Time is set to 24. If the part has a Lead Time of 0, 24 is assumed.

-

Regular Stock OFC 9—for regular stock orders, the Lead Time is set to anything but 24 or 0.

Quarterly OFC 9

To ensure that sufficient inventory is maintained during periods of low demand, the Reorder Point for quarterly order code 9 parts is always calculated as a percentage of the last 12 months sales (L12).

During the regular stock order run, if the On Hand quantity drops below the Reorder Point an order is triggered to replenish the stock even though it is not a quarterly order. The percentage that is applied to the last 12 months sales is configured in the Safety Stock field. If the Safety Stock is blank, 10% is assumed.

The steps the system uses in the calculation are:

-

Apply Effectual %. If the part has no Effectual %, the sales history is not adjusted. If the part does have an Effectual %, it is applied to the sales history as described for OFC 1.

-

Calculate the Reorder Point as:

Safety Stock (use 10% if zero) x last 12 months sales history (L12) (after being adjusted by Effectual %).

For example, assuming the part had a Safety Stock of 10%, 268 sales in the past 12 months, and 0 Effectual %, the calculation is:

0.10 x 268 = 26.8 or 27 Reorder Point

This Reorder Point is loaded to the Reorder Point field on the Parts Profile.

If the Reorder Point is calculated as less than zero, use zero.

-

It is now determined whether this is a normal stock order or a quarterly order (i.e., whenever the stock order is run, the terminal operator must indicate whether this is a regular stock order or a quarterly order).

- If this is a quarterly order go to the next step.

- If this is a regular stock order go to step G.

-

The system calculates the estimated demand for the next quarter using the following formula:

Sales 12 months ago + Sales 11 months ago + Sales 10 months ago (after being adjusted by Effectual %)

For example, assuming the part had 38 sales 12 months ago, 12 sales 11 months ago and 74 sales 10 months, the calculation would be as follows:

38 + 12 + 74 =

124 (Estimated demand for next quarter) -

The system calculates the estimated demand for the quarter following the next quarter using the following formula:

Sales 9 months ago + Sales 8 months ago + Sales 7 months ago

For example, assuming the part had 29 sales 9 months ago, 30 sales 8 months ago, and 20 sales 7 months ago, the calculation would be as follows:

29 + 30 + 20 =

79 (Estimated demand for the quarter after next quarter)If the estimated demand for the quarter after the next quarter is less than the Reorder Point calculated in step B, then the Reorder Point will be used to calculate the required Order Quantity in the following formula:

Sales 12 months ago + Sales 11 months ago + Sales 10 months ago (after being adjusted by Effectual %) + Reorder Point or (Sales 9 months ago + 8 months ago + 7 months ago), depending on which is larger =

124 + 79 =

203 (Order Quantity) -

The Order Quantity is then reduced by the current On Hand + On Order + On Back Order quantities.

If the result is positive, an order is required for that quantity.For example, assuming the part had an On Hand quantity of 20, an On Order quantity of 0 and an On Back Order quantity of 0, the calculation would be as follows:

203 - 20 - 0 - 0 =

183 (Order Quantity)Note: If the part had a package quantity of 10, this figure would be rounded up to 190.

The Order Quantity calculated in this step will be added to the Order Quantity field on the Parts Profile (before being adjusted by Package Quantity and Set Quantity).

The order calculation for a quarterly OFC 9 part would now be complete.

-

Regular Bi-Weekly Order Only

This step is only performed if a regular bi-weekly stock order is being run.

The Order Quantity is calculated using the following formula:2 x (Reorder Point - On Hand - On Order - On Back Order)

As such, using the Reorder Point calculated in step B and the On Hand, On Order, and On Back Order quantities listed in step F, the calculation would be as follows:

2 x (27 - 20 - 0 - 0) =

54 - 20 =

34 (Order Quantity)Note: If the part had a package quantity of 10, this figure would be rounded up to 40.

The Order Quantity calculated in this step will be added to the Order Quantity field on the Parts Profile.If the quantity is less than zero, no number is calculated.

Regular Stock OFC 9

A regular OFC 9 part is processed and ordered during a regular stock order as opposed to a quarterly stock order. The formula used to calculate the Order Quantity for these parts differs from those which are ordered quarterly.

The steps the system uses in the calculation are:

-

Calculate the Reorder Point as:

Safety Stock (use 10% if zero) x last 12 months sales history (L12) (after being adjusted by Effectual %)

For example, assuming the part had a Safety Stock of 10%, 268 sales in the past 12 months and 0 Effectual %, the calculation is:

0.10 x 268 = 26.8 or 27 Reorder PointThis Reorder Point is loaded to the Reorder Point field on the Parts Profile.

If the Reorder Point is calculated as less than zero, use zero.

-

The expected sales during the Lead Time specified on the part is calculated and affects the Order Quantity of the part. Lead Time is specified in weeks whereas sales history is maintained by month. When calculating the expected sales during the Lead Time, one month is assumed to equal 4 weeks.

When running the stock order, the terminal operator must enter what week of the month it is. After doing so, the system calculates the required Order Quantity based on the week the stock order is being run and value entered in the Lead Time field.

For example, if the stock order is created on week 1 of the month, the Lead Time on the Parts Profile was 5, the sales for this month last year was 38, and the sales for the next month of last year was 12, the Order Quantity is calculated as:

3 weeks (or 75% of the sales for this month last year) + 2 weeks (or 50% of the sales for next month last year) =

(0.75 x 38) + (0.50 x 12) =

28.5 + 6 =

34.5 or 35 (Order Quantity)If the value after performing this calculation is negative, use zero. (Parts returns can cause negative sales history.)

Alternatively:

-

If the stock order was being created in week 2 of the month, the Order Quantity would be calculated as:

50% of the sales for this month last year + 75% of the sales for next month last year -

If the stock order was being created in week 3 of the month, the Order Quantity would be calculated as:

25% of the sales for this month last year + 100% of the sales for next month last year -

If the stock order was being created in week 4 of the month, the Order Quantity would be calculated as:

0% of the sales for this month last year + 100% of the sales for next month last year + 25% of the sales from 10 months ago

-

-

The Order Quantity is reduced by the current On Hand + On Order + On Back Order quantities.

For example, assuming the part had an On Hand quantity of 20, an On Order quantity of 0 and an On Back Order quantity of 0, the calculation would be as follows:

35 - 20 - 0 - 0 =

15 (Order Quantity) -

The Order Quantity + On Hand + On Order + On Back Order quantities are compared to the Reorder Point (Safety Stock) of the part. If the Order Quantity + On Hand + On Order + On Back Order is less than the Reorder Point, the Order Quantity is increased so that it matches the Reorder Point.

In this case, the Order Quantity + On Hand + On Order + On Back Order is 15 + 20 + 0 + 0 = 35, and the part has a Reorder Point of 27. As such, no adjustment is made. If the Reorder Point had been 40 however, then 5 more parts would be added to the Order Quantity.

OFC D Calculation

This code is used for slow moving parts, (10 sales or less per year with no more than 2 sales Demands in any month).

When assigned to a part, OFC D attempts to maintain an On Hand quantity of 2 at all times. If the On Hand + On Order + On Back Order quantity for a part with OFC D assigned to it is less than 2, then an order is required. If an order is required, then enough parts are ordered to bring the On Hand quantity of the part to 2, with a maximum of 2 parts being ordered at any one time.

For example, if a part has an On Hand quantity of 2 and 1 is sold, then 1 part will be ordered. If that same part had an On Hand quantity of 2 and 2 are sold however, then 2 will be ordered.

Revision: 2025.02