Parts Profile

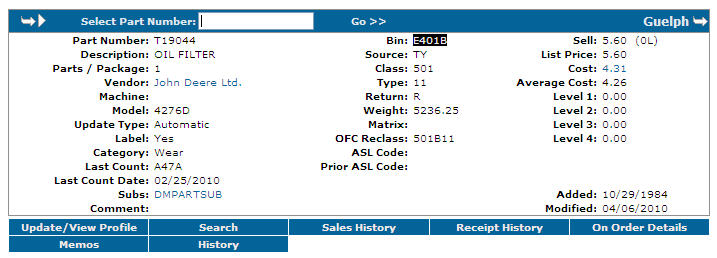

The Parts Profile screen displays detailed information for the selected part. See also Parts Substitution Notes.

Click on the Previous, Change, or Next![]() icon in order to scroll to the previous part number on the list, search for a different part number, or scroll to the next part number on the list.

icon in order to scroll to the previous part number on the list, search for a different part number, or scroll to the next part number on the list.

The search field appears on the Parts Profile screen:

| Field | Description |

|---|---|

| Select Part Number | Enter another part number and click Go >> to display profile information of the selected part. |

Use these buttons to complete your work on the Parts Profile screen:

| Button | Function |

|---|---|

| Back | Closes the Parts Profile screen and returns to the Parts tab. |

| Label | Opens the Select Print Parameters screen allowing you to print parts labels. |

The sections on the Parts Profile screen are:

Note: Field level-security assigned to your user profile (as defined on the Field - Work With Field Level Security screen) may change the appearance of or hide certain fields.

Main Section

The fields appear on the Parts Profile screen:

| Field | Description |

|---|---|

| Part Number | The part number assigned to the selected part. |

| Description |

A brief description of the part. |

| Parts/Package |

The quantity of parts purchased from a vendor in a single package. The parts per package signifies how the system will maintain inventory on this part. For example, a vendor may only sell you oil filters in cases of 12, but you can number and sell them individually from your store. When you receipt the part however, you would receipt it as a quantity of 12. The price and cost loaded on this part should be the list price of one whole package. When the part is sold, the selling price and cost is divided by the Parts/Package to calculate the selling price and cost for a single item. Note: If the Use the same Parts Per Package for all locations setting is activated on the System Settings: Division screen, the value in this field must remain the same across all branch locations. |

| Vendor | The vendor number for the supplier of this part. |

| Machine | The machine number that the part can be used on. |

| Model | The model number of the machine that the part can be used on. |

| Update Type | Used to determine if a price update run should automatically update the parts master file or whether it is going to be maintained manually. |

| Label | Indicates whether a label is to be printed for this part number when it is receipted through the Parts Ordering screen. |

| Category | Indicates if the part is categorized as a Wear part. A Wear part indicates that the part naturally wears and is not covered under warranty (e.g. filter or brakes). Wear parts are omitted from the parts highlighting rule (indicated by the Warning icon -flashing triangle) that appears on the Work Order Parts Requisition Details tab. |

| Last Count | The last inventory count which included the selected part. |

| Last Count Date | The date of the last inventory count. |

| Subs | If this part subs to another part, the substitute part number is displayed. Clicking the hyperlinked part opens the Part Profile for that sub part. |

| Reman | If this part is a re-manufactured part, the part number for the associated part is displayed. Clicking the hyperlinked part opens the Reman/Core tab for that part or, if no remanufactured part exists, the Add Part screen. |

| Comment | An alternate description or note about the selected part. |

| Bin |

The bin number indicates the part's physical location. If this field appears highlighted, alternate bins exist. Move the cursor over the Bin number to view alternate Bin location numbers. If applicable, the part's previous bin number appears in brackets next to this field. |

| Source |

The part's source of supply code. This typically represents the part's originating warehouse location. Valid source of supply codes are configured and listed on the Source of Supply screen. |

| Class |

The class code of the selected part. In conjunction with the Type code, the class code is used to group similar parts together. Valid class codes are configured and listed on the Classes screen. |

| Type |

The type code of the selected part. In conjunction with the Class code, the type code is used to group similar parts together. Valid type codes are configured and listed on the Types screen. |

| Return |

The return code for the selected part, which indicates whether it is returnable. New return codes are configured on the Return Codes screen, however vendor-supplied return codes are not configurable within IntelliDealer. For more information regarding a specific vendor's return codes, contact the vendor. This field will appear highlighted if the selected part number is on an active surplus return. Hover over the field label to display the surplus Return Number. |

| Weight | The metric weight of the part. |

| Matrix |

The price matrix associated to the part. The system uses this to determine the proper price increase percentage for the part. Valid price matrices are configured and listed on the Price Matrix screen. |

| OFC Reclass | Whether this part is affected by the OFC reclass run. |

| Sell | The selling price of the part. The parts sell price may be affected by the Parts/Package field. |

| PIP | The price increase percentage for the selected part (as specified in the Increase % field on the Parts Profile tab). The alpha character next to the value in this field (C or L) denotes whether the increase percentage will be applied to the Cost or List price of the part. |

| List Price | The part's suggested list price. |

| Cost | The net cost of the part. |

| Average Cost |

The average cost of a part is calculated using the Landed Cost |

| Level 1, Level 2, Level 3, Level 4, | The pricing levels of this part. These levels refer to such things as wholesale price, fleet price, jobber price, etc. |

| Added | The date the part profile was added to the system. |

| Modified | The date the part profile was last modified. |

You can drag and drop the Sales Summary, Availability, Ordering Information, and Additional Information sections as indicated by the Drag/Drop icon ![]() , allowing you to customize the order of the sections that appear on the Parts Profile screen.

, allowing you to customize the order of the sections that appear on the Parts Profile screen.

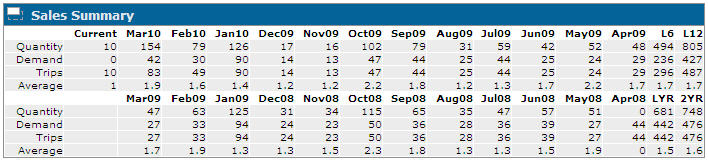

Sales Summary Section

The fields on the Sales Summary section of the Parts Profile screen are:

| Field | Description |

|---|---|

| Rows | |

| Quantity | The number of parts sold per month. |

| Demand |

A single demand entry (1) is made by each parts invoice to a part's profile regardless of the number of times that part is sold on that one invoice. Also, only one credit demand entry (-1) is made by each parts invoice regardless of the number of times that part was returned on that one invoice. However, if a part is sold (1) and returned (-1) on the same parts invoice the demand entry is zero because 1 +(-1) = 0.

|

| Trips | The number of physical trips to the part's bin. |

| Average | The average between the quantity of the part and the number of bin trips. |

| Columns | |

| Current |

Values appearing in this column are for activity to date in the current month. |

| L6 | Values in this section of the column refer to the most recent six month period. |

| L12 | Values in this section of the column refer to the most recent twelve months of activity. |

| LYR | Values in this section of the column refer to the sales quantity for the last fiscal year. |

| 2 YR | Values in this section of the column refer to the total sales quantity from two years ago. |

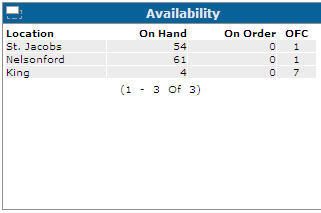

Availability Section

The fields on the Availability section of the Parts Profile screen are:

| Availability | |

|---|---|

| Field | Description |

| Location | The branch location that stocks the selected part. |

| On Hand |

The number of parts the corresponding branch location has in stock. A 'future rental adjusted' value appears in red colored text on parts for non-serialized rentals so that the true On Hand value is displayed without having future rentals considered in the quantity. |

| On Order | The number of parts the corresponding branch location has on order. |

| OFC |

The order formula code for the part in the corresponding branch location, which determines the amount of parts to order on the next stock order shipment. For more information regarding order formula codes, see the Order Formula Codes Summary. |

Click on a Location to switch from your default branch location to another branch location.

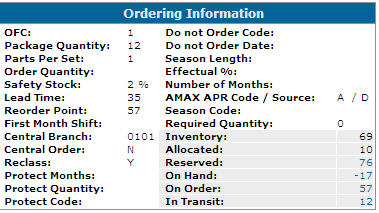

Ordering Information Section

The fields on the Ordering Information section of the Parts Profile screen are:

| Ordering Information | |

|---|---|

| Field | Description |

| OFC |

The order formula code for this part. This code determines the method to be used in computing the order quantity for a part. For more information regarding order formula codes, see the Order Formula Codes Summary. |

| Package Quantity |

The minimum package quantity that the supplier sells the part in. (e.g. the part could come in a package of 10). |

| Parts Per Set | If the part is normally sold as a set this field lists the number of parts in a set. The system reorders parts for this item to maintain at least one complete set in inventory. |

| Order Quantity |

The number of parts needed the next time the part is ordered. For some order formula codes you can set the order quantity manually, but for other order formula codes system automatically calculates the quantity. |

| Safety Stock | Maintains parts in stock so you don't run out of stock. Maintained as a fixed amount or as a percentage of sales history, F (fixed) or % (for percent). |

| Lead Time |

The time (in weeks) it takes the vendor to ship the parts, or the number of weeks between the time part should be ordered and the time that the parts are actually received. |

| Reorder Point | The minimum on hand amount the part can reach before an order is placed. |

| First Month Shift |

Shifts the sales history used in calculating stock orders. The sales history can be shifted forwards or backwards a specified number of months. In the first month shift field, if this year's sales activity is expected to be one month earlier than last year, enter 01. If this year's sales activity is expected to be one month later, enter 1. |

| Central Branch | If selected, indicates which location will act as a central location as set up in the stock transfer and central inventory parameters. |

| Central Order | If selected the system includes this part's sales history in the central ordering branch even if it is a stocking part. If not selected, the system would only include sales history of parts that had either an OFC of 5 or a don't order code. |

| Reclass | Indicates whether this part is affected by the OFC reclass run. |

| Protect Months |

Indicates the number of months this part is protected from stock transfers. This is NOT a mandatory field but works in tandem with the Protect Code field. Note: The Months field automatically counts down after each parts month end is run. When the countdown reaches zero, the part is no longer protected. |

| Protect Quantity | The quantity of the part that is protected from stock transfers. This is also NOT a mandatory field. This field is used to determine if there is a minimum quantity you want to protect. E.g. with 4 units of a part protected and with 20 on hand then a transfer of 6 based on the surplus transfer criteria will be suggested. |

| Protect Code |

The protect code is assigned to parts to indicate that the part is to be excluded from all parts transfers. This code is a dealer defined code and has no edit controls for it's value. The code can also be a number or a letter. This code is also blank by default and is not a required value. Most dealers use this as a letter (eg N - new part for a new model of equipment that they want to protect.) You can use the code by itself or to indicate that number of months you want it protected if you like the number of quantities to protect. Additionally, this code is part of the surplus transfer screen and is used to indicate whether you want to include or exclude protected inventory on surplus transfers. Note: Once a protective inventory code (CD) has counted down to zero it resets the CD and Months field to blank. |

| Do Not Order Code | Must be D or blank. Code D will prevent the part from being ordered on a stock order. |

| Do Not Order Date | This field indicates that this part is not ordered on a stock order until the first stock order in that calendar month. For example, 03 represents March. If this field is blank, normal parts ordering will occur. |

| Season Length |

Used in conjunction with the Do Not Order Date. The number of months (01 to 09) that the part is considered in season, indicating the number of months the part is ordered. |

| Effectual % | If you expect an increase or decrease in sales for this part, enter the percentage increase or decrease in this field (e.g. 50 = 50%). |

| Number of Months | Refers to the month when the effectual % no longer applies. |

| AMAX APR Code/Source |

The APR code indicates whether AvailabilityMAX controls replenishment for the selected part. The source code indicates the location the part is ordered. |

| Season Code | This code is used to apply a special forecast designed to take the seasonality of the part into account when the forecast is calculated. |

| Required Quantity |

The minimum required quantity of a given part that needs to be stocked at the dealership location. This field is only visible if Configuration > Interfaces > CNH > AMAX is Active. |

| Inventory | The quantity of parts in stock at the start of your business day (since the last billing run), plus any receipted shipments or inventory adjustments. |

| Allocated |

The quantity of allocated parts. Note: Parts sold on an invoice or work order parts requisition are shown as reserved, (not allocated), until the next billing run. |

| Reserved | The quantity of parts that have been reserved. A part is considered reserved when the part is entered as a non-serialized rental, the part is issued on a sales order, the part is issued on a work order requisition, the part is put on reserve using cash code R, a Machine Down or Field Inspection order has been created to special order the part, and then receipted in using the Part Ordering screen, causing the part to be issued. Parts are no longer reserved after a sales order billing run has been processed. |

| On Hand | The quantity of parts in stock (Inventory) less the number of parts Allocated or Reserved. |

| On Order | Quantity of parts currently on order with the supplier. |

| In Transit | Quantity of parts currently in transit. Click on the quantity to see a list of all pending order receipts for the selected part. |

The APR codes are:

The Source codes are:

| Source Codes | |

|---|---|

| Code | Description |

| D | This part is ordered through a depot. |

| S | This part is ordered through a CNH ship direct promotion. |

| A | This part is ordered through an Allied depot. |

Click on the Reserved quantity to view all of the customers who have reserved the selected back ordered part.

Click on the On Hand quantity to open the Parts Availability screen.

Click on the On Order quantity to display all current orders that include the selected part number.

Click on the In Transit quantity to view a list of pending order receipts for the selected part number.

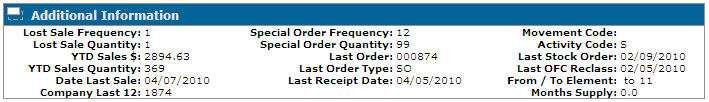

Additional Information Section

The fields on the Additional Information section of the Parts Profile screen are: