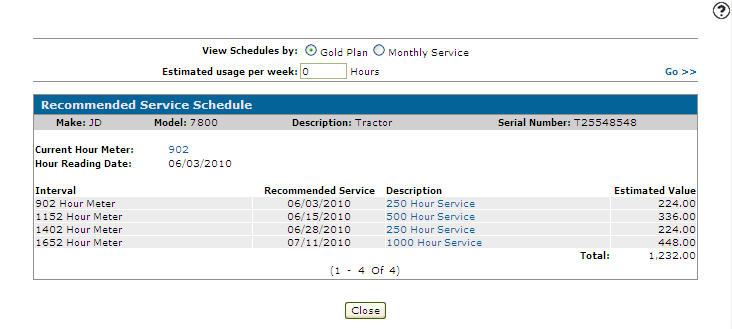

Recommended Service Schedules

Use the Recommended Service Schedules screen to view the recommended service schedules for a piece of equipment.

To open the Recommended Service Schedules screen, click the Recommended Service link on the Equipment Profile screen.

The selection fields on the Recommended Service Schedules screen is:

| Field | Description |

|---|---|

| View Schedules by |

Select a method to view recommended service schedules. Methods vary depending on schedules loaded. |

| Estimated usage per week |

An estimate of how many hours per week this equipment is used. Defaults to 7. This field only appears when the schedules are based on hours. |

The fields on the Recommended Service Schedules screen are:

| Field | Description |

|---|---|

| Make | The manufacturer of the unit. |

| Model | The model number on the unit. |

| Description | A brief description of the unit. |

| Serial Number | The unit's serial number. |

| Current Hour Meter | The current hour meter reading for the selected unit. |

| Hour Reading Date | The date the hour meter reading for the unit took place. |

| Interval | The recommended service interval, indicating at what hour interval the unit requires service. |

| Recommended Service | The recommended date for the service. |

| Description | A brief description of the recommended service. |

| Estimated Value |

The estimated cost for the recommended service. To calculate this value, the system uses the average cost of the history entries associated to the selected job code, plus the total price of any parts on the job code. The number of history entries the system uses to calculate the average job code cost is configured in the Service Agreement Management Flatrate History Search Entries field of the System Settings. For example, if the value in this field is 10, the system uses the last 10 history entries (starting from the most recent) to calculate the average cost. To calculate the part price, the system uses the list price of the part (as specified in the Master Price File) divided by the Parts Per Package value (as specified in the PARTMAST file/ parts profile). This price is added to the average cost of the job code to calculate the Estimated Value. If there are no history entries for the selected job code (or if the average cost of the history entries is zero), the system multiplies the Job Code Hours (as specified on the Job Code Details screen) by the Work Order Rate Per Hour for the 'PM' (planned maintenance) employee profile (as specified on the Service Information tab), then add the price of the parts associated to the job code to calculate the Estimated Value. |

Click on the Current Hours Meter link to open the Update Hours screen.

Click on a service Description to open the Job Code Details screen.

Click Close to complete your work on theRecommended Service Schedules screen.