Parts Month End

Warning: Once a month end is closed, it cannot be reopened. This includes Accounts Receivable, Accounts Payable, General Ledger, and Parts month ends. Do not close any month end until you are certain of the details of each transaction in the month.

The following is the is description of the Demand buckets in Parts Profile and how the demands are calculated.

IntelliDealer Demands Buckets.

1) 24 demand buckets in the file PARTMAST

2) OFC reclass uses demands

3) OFC codes logic uses demands buckets, not bin trip buckets

4) Demand buckets appear on IntelliDealer Parts Profile screen.

5) Details on how demands are calculated are below

Demand Calculation

- The logic used for Demand calculation is 1 demand per part per sales order/requisitions, per sign, regardless of the number of lines the part is on or the number of times the part is back ordered or invoiced. This means if there are two sales and one return there is no demand logged because there is ultimately one negative demand and one positive demand, which offset. Based on this the dealer may decide to not allow users to add parts to an invoiced sales order/parts invoice.

- For parts sales through equipment & rental it is 1 demand per line item per invoice.

- IntelliDealer shows the demand buckets in the Order information tab.

- Branch transfers will never record demands. This would be anything cost coded as 'Transfer' or NSC 'T'

- The PARTLS table will determine if lost sales record demands.

- One time sales will not record demands. This would be anything cost coded as a 'One time Sale' or NSC 'A'

- Deere percent of fill calculations use line items for this calculation, so there is no reference to demand buckets.

- Work order adjustments are treated as demands based on the following logic (Demand calculation change - March 2009 )

- If '$W/O ADJ$' is in the ship via field, then do not include these records in the demand calculation since this is an adjustment to an existing line

- If '$W/O ADJ/REV$' is in the ship via field, then include these records in the demand calculation since this is reversing the original line

- Surplus returns can be setup to be handled as abnormal sales so that no demand details are affected.

Note: All Dealers should be ensuring that lost sales are being captured properly. As part of the process, we check to see if the part is loaded more than once on the document and if so we wait to handle the demand value until that first line is processed. So if the first line is cancelled or removed, the system would miss the demand for any subsequent line for that part. IntelliDealer has a switch that will not allow the users to clear a line and will require the line to be processed as a lost sale. The PARTLS table can be configured to determine which lost sale values affect demands. The capture of demands is also critical in the sending of the proper data all inventory replenishment interfaces such as CNH AMAX, AGCO API, Volvo MMI, John Deere JDPrism and Komatsu RIM 2.0.

The Parts Month End screen closes the parts month, and produces a parts management report for the month. See Performing a Parts Month End.

To open the Parts Month End screen, click the Month End link on the Parts list of the Product Support Quick Links screen.

Topics in this section are:

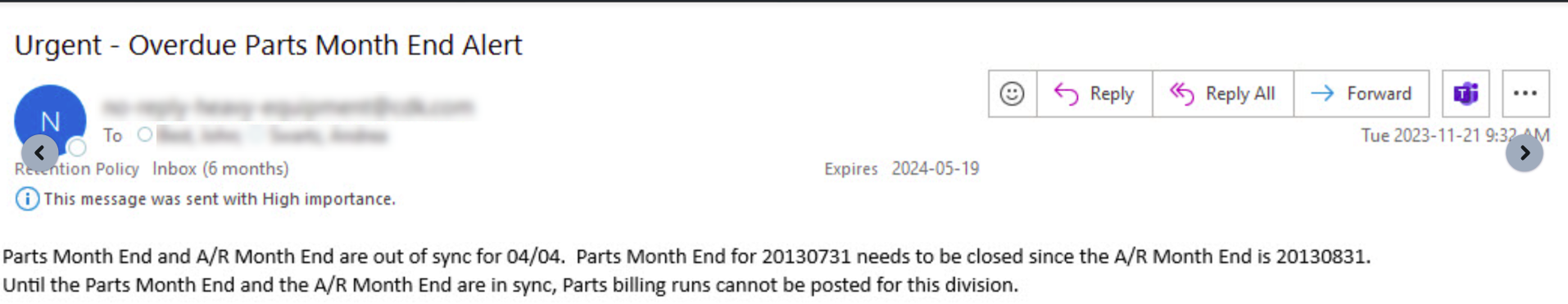

Parts Month End Warning Email

During the nightly full database run and the shortened day-end (also called a skinny database) IntelliDealer checks to compare the part and accounts receivable (A/R) month end dates for active divisions. If the next parts month end date is less than the next A/R month end date, then an email is sent to the dealership to warn that the month end dates are out of sync. This is because no billing runs can be processed in a division until the parts month end is the same or ahead of the A/R month end date. The only reason IntelliDealer allows the next parts month end date to be ahead of A/R is in case someone accidentally closes parts ahead of schedule.

Configuring the Parts Month End Warning Email

You can verify the dates compared by navigating to the Configuration > Miscellaneous > Other > System Settings screen, click the Division tab, and examine the Next Month End – Parts and Next Month End – Accounts Receivable parameters (see Month-end Dates).

You can configure where the email is sent by navigating to Administration > Settings > System Notification Emails and setting the email addresses for Overdue Parts Month End Alert. See System Notification Email Address.

While not recommended for divisions invoicing parts, you can turn off the notification email by navigating to the Configuration > Miscellaneous > Other > System Settings screen, click the Division tab, and under the Parts section deactivate the Overdue Parts Month End Alert checkbox (see Overdue Parts Month End Alert).

Parts Month End Screen Description

The fields on the Parts Month End screen are:

| Field | Description |

|---|---|

| Month End Date | Enter the closing date for the parts month end. |

| Printer | Enter the printer selected to print the parts month end. |

| or PDF | Select whether or not you would like to create a PDF file of the parts month end, which can be viewed via the PDF Viewer. |

Closing the parts month causes the following to occur:

-

The current months sales quantity is loaded into the corresponding sales history bucket. The current months sales quantity is then reset to zero in order to start accumulating the next months sales quantities

-

The last 24 months sales history is shifted one month on the Parts Profile screen

-

The average inventory (quantity) for the fiscal year is updated as follows: old average inventory x month number of the fiscal year being closed - 1 + new average (current on hand)

-

Month number of the fiscal year being closed

-

The service management totals will be calculated. If the John Deere Service Management feature is enabled, the Service Management Information report will print the totals for all locations, and the transmission file will be created for all locations.

The average inventory will be reset to the current on hand when the first month of the fiscal year is run. If the month being closed is the last month of the fiscal year, then:

-

Last years sales quantity is moved to two years ago

-

The last 12 months sales are accumulated and moved to last years sales quantity

-

The lost sale frequency and quantity are reset to zero

-

The special order frequency and quantity are reset to zero

-

The year to date sales dollars is moved to last years sales dollars. The year to date sales dollars is then reset to zero in order to start accumulating sales dollars for the next year

Use these buttons to complete your work on the Parts Month End screen:

| Button | Function |

|---|---|

| Continue | Runs the parts month end reports: Parts with No Costs, Parts Management Versus G/L, Management Information, Management with Transfer Information, Type Code Information. |

| Close | Closes the Parts Month End screen and returns to the Product Support Quick Links screen. |

Parts Month End Reports

The Parts Month end produces these reports:

-

PAR184 - Protective Code

-

PAR206 - Type Code Information

Note: The PAR206 report is generated during the parts month end process if the Parts Month End field is set to print on the System Settings: Company screen.

-

PAR29A - Parts Management with Transfer Information

-

PAR086 - Parts Management Versus G/L

Reprint Parts Month End Screen Description

Use the Reprint Parts Month End screen to reproduce the parts management reports PAR029 and PAR206 for the previously closed month in the current fiscal year. The information is a reprint and not a recalculation.

To open the Reprint Parts Month End screen, click the Reprint Parts Month End link on the Parts Reports screen.

Note: You cannot generate reports for the previous fiscal year.

The fields on the Reprint Parts Month End screen are:

| Field | Description |

|---|---|

| Month End Date | The month end date for which you want to produce the reports. |

| Transmit PMManage Data | If selected, re-transmits PMManage data to John Deere. |

| Printer | The printer that the reports will be printed from. |

| or PDF | If selected, generates a PDF of the reports instead of printing them. |

Use these buttons to complete your work on the Reprint Parts Month End screen:

| Button | Function |

|---|---|

| Continue | Generate the PAR029 and/or the PAR206 reports. |

| Close | Close the Reprint Parts Month End screen without generating the reports. |