Wireless Inventory: Parts Inventory Control

Parts Inventory Control ensures that your dealership's inventory is more complete and more accurate. This is achieved through reduced manual data entry, faster data capture, and fewer errors.

You and your dealership are more cost-efficient, and customer satisfaction increases as a result of your employees' instant access to data and the fact they are able to discuss inventory more accurately, more quickly, and from anywhere in the dealership.

Inventory power is increased as Parts Inventory Control is designed to allow dealership personnel the ability to perform cyclical inventory counts on a regular basis—and without keeping everyone off the business system. Parts Receipting allows you to record parts orders as they enter your shipping/receiving area and allows you to receive multiple emergency orders, or a single stock order, in one step.

Streamline processes as you walk down your parts aisles, select items off the shelves, and then create a list by scanning the barcode. This eliminates the need for keypunching, reducing errors and speeding up the checkout process. As well, Parts Inventory Control gives the user the ability to quickly and easily modify the bin location without having to write the number down and remember to change the parts record in the system—the change you make is instantly reflected in the business system.

Topics in this section are:

The Parts Inventory Control system is made up of several applications that assist your dealership. They include: Parts Count, Parts Receipting, Picking List, Quick Check, Stock Movement and Shop Parts Return.

Note: Only the options you are authorized to access appear on the menu.

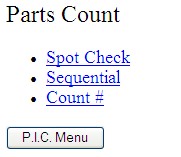

Parts Count

Parts Count is designed to allow dealership personnel the ability to perform cyclical inventory counts on a regular basis and without keeping everyone off the business system. This application contains three methods for performing counts: Spot Check, Sequential and Count Number. The information collected is loaded directly into the existing Inventory Count application in the System. This allows you to take advantage of all the existing features including variance reporting and the inventory update facilities.

Spot Check—allows a dealership to count inventory randomly by recording the parts and quantities in any order according to the user.

Sequential—count allows you to select a starting bin location and the system prompts you to perform a count consecutively starting at that bin location.

Count Number—can be used to prompt each part to be counted by bin location for a previously created count, and pick up a count where you left off for a previously created count.

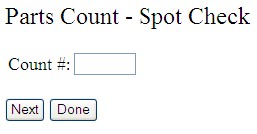

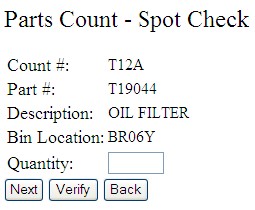

Spot Check

This function can be used to count one random part at a time in your inventory, in no particular sequence.

-

Select Spot Check.

-

Enter a Count Number.

-

Click Next to continue.

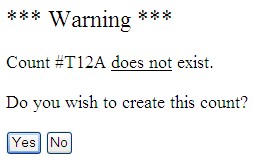

If the Count does not exist yet, you are warned and offered the chance to create the count in the Inventory Count application in IntelliDealer.

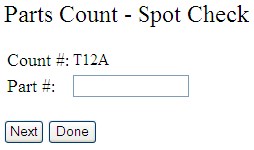

If the count exists already the system lets you add to the existing count.

-

Enter or scan the Part # and click Next.

The screen updates with information about the selected part.

Note: If the Show On Hand Quantity on Parts Count Screens switch is activated in security system 990 in IntelliDealer, the On Hand quantity of the selected part is displayed and you are forced to enter a count Quantity on this screen (there is no option to Verify the current inventory in the system). If you do not have access to the security settings at your dealership, contact your system administrator.

-

Enter the Quantity you have on hand.

-

Click Next to save the quantity value and continue counting another part on this Count #.

-

or -

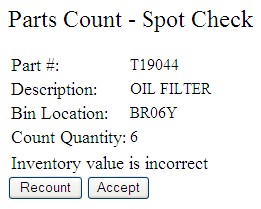

Click Verify to check the quantity you've entered against the current inventory in the system.

You are then asked to either Recount or Accept any non-matching quantity.

-

or -

Click Back to ignore the quantity you entered and continue counting another part on this Count #.

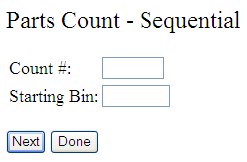

Sequential

A sequential count is used to perform counts on a range of bins. A starting bin is entered and the system automatically moves to the next bin after each part number is counted.

-

Select the Sequential link.

-

Enter the Count Number.

If the Count Number does not already exist you are prompted to create it or add to an existing one.

-

Enter the Starting Bin.

-

Click Next to continue to the first part in this bin.

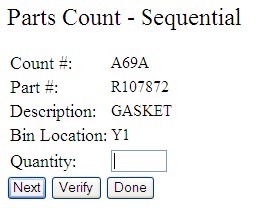

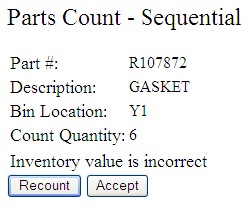

The screen displays information about the selected part in the selected bin.

Note: If the Show On Hand Quantity on Parts Count Screens switch is activated in security system 990 in IntelliDealer, the On Hand quantity of the selected part is displayed and you are forced to enter a count Quantity on this screen (there is no option to Verify the current inventory in the system). If you do not have access to the security settings at your dealership, contact your system administrator.

-

Enter the Quantity on hand.

-

Click Next to save the quantity value and continue counting parts in the next bin location on this Count #.

-

or -

Click Verify to check the quantity you've entered against the current inventory in the system.

You are then asked to either Recount or Accept any non-matching quantity.

-

or -

Click Done to finish with the sequential count.

If you come back to this count at a later time you are able to continue from the last bin.

-

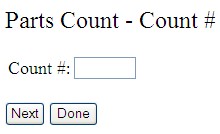

Count #

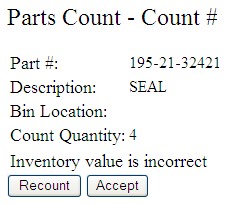

A count number count is to continue a numbered count that was already created in either IntelliDealer or the Parts Inventory Control system. A count number is entered and the system automatically starts at the next part number in the count.

-

Select the Count # link.

-

Enter the Count Number.

-

Enter the Quantity on hand.

-

Click Next to save the quantity value and continue counting the next part on this Count #.

Receive Parcels

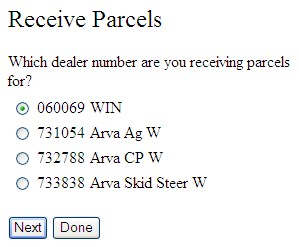

If you are a John Deere dealer, this application allows you to scan in and verify if parcels received using John Deere's Get Shipped Parcels interface are for your dealership. Once received, a confirmation (or return notice) is sent back to Deere automatically.

-

Select the Receive Parcels link on the Parts Inventory Control screen.

-

Select the receiving dealer from the list.

Note: The dealer numbers listed here come from those loaded in Vendor Profile – Dealer tab for vendor DEERE and the location you are assigned to.

-

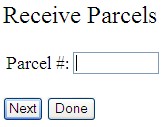

Enter or scan the barcode or enter the Parcel # and click Next.

If the parcel number is meant for your dealership/location, you see a Valid Parcel message.

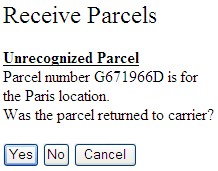

If the parcel number is not intended for your dealership, you see an Unrecognized Parcel message.

-

When you are finished scanning parcels, click Done on the Receive Parcels screen. A record of the scanned parcels is then sent to John Deere recording which location has received or returned which Deere parcels.